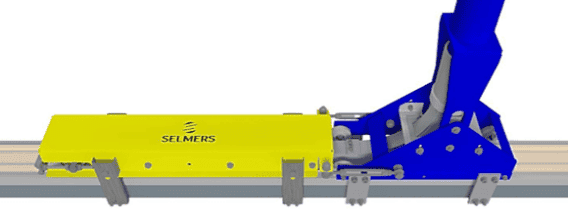

Abrasive acceleration belt

The Abrasive Acceleration Belt ensures a constant and controlled supply of abrasives during the blasting process, which prevents abrasives from bouncing off the supply belt of the internal blasting system. This new concept is improving the quality of the blasting process, eliminates HSE risks, saves the use of abrasives and extends the lifetime of the blasting equipment.

Advantages:

- No bouncing abrasives

- Improved blasting result by constant abrasive flow

- Improved Health and Safety

- Clean work space due to closed loop

- Less spill of abrasives

- Improved lifetime of the blasting equipment

- Easy to integrate into existing blasting

How It Works:

The supplied abrasives fall through the grit foot onto the supply belt of the blast lance. Due to difference in speed, abrasives tend to bounce on the belt. The new Abrasive Acceleration Belt encloses and accelerates the supplied abrasives to the same speed as the supply belt, neutralising potential energy that bounces abrasives.

The Full Scope:

- Complete grit foot extension set

This system can also be found as a part of the:

Product Range:

Types of grit foot : Applicable to Selmers A-, B-, and C-blast heads

Filterable Properties:

At Selmers, we specialize in advanced industrial machinery and automation for coating and handling pipes and tubes. With over 50 years of experience, we have grown into a trustworthy supplier of numerous automated solutions. Collaboration is key to creating real magic. Interested in optimizing performance and reducing risks?