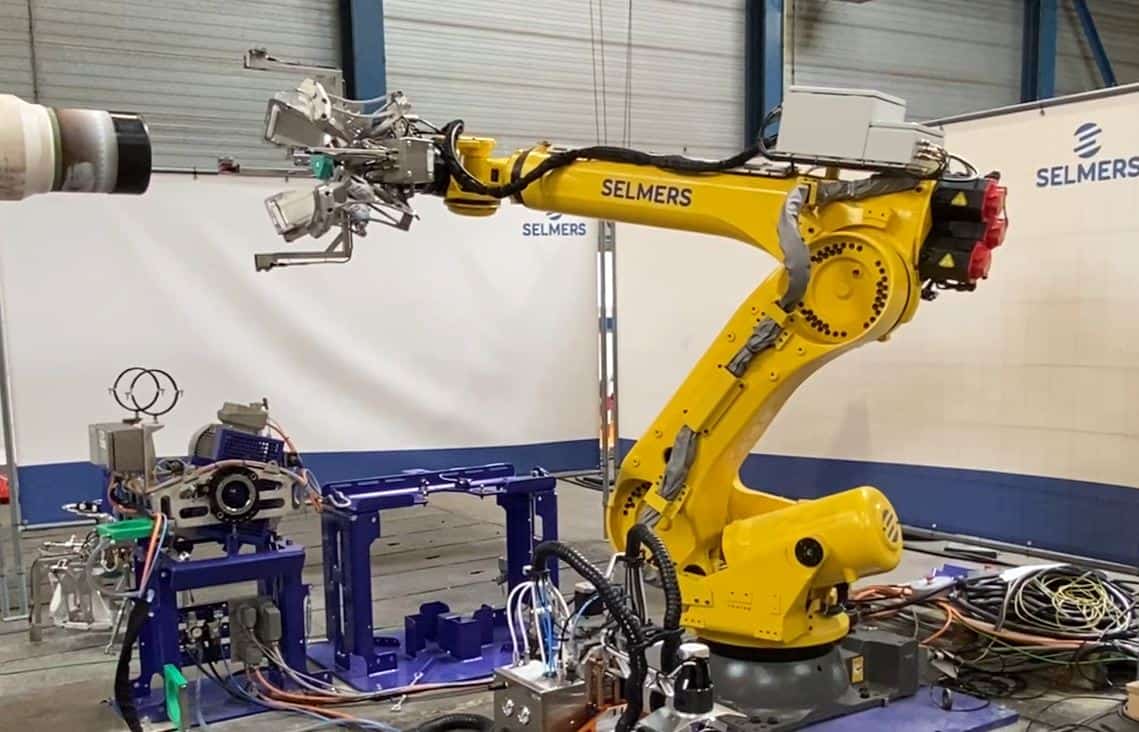

Nowadays robotics is an essential component in many modern manufacturing environments. They enable production processes to be faster, flexible, safer and more reliable. Selmers believes that each production facility, big or small, can benefit from the advantages of robotic process solutions.

Selmers has developed a range of robotic solutions which are valuable for the pipe processing industry and which may optimize any specific production process. Above that, we would like to be challenged. If you are considering to optimize or automate your production process, get in contact with us. We would be pleased to think together with you on the best fitting solution. Examples of processes we have approached with robotics to answer customers’ challenges so far: brushing, blasting, grinding, sanding, de-icing, coating, tooling, measuring and marking.

Advantages:

Make your facility future-proof

Full integration with your production process

Improved quality of work for your employees

Increase your production manufacturing flexibility

Reduce operating costs

How it Works

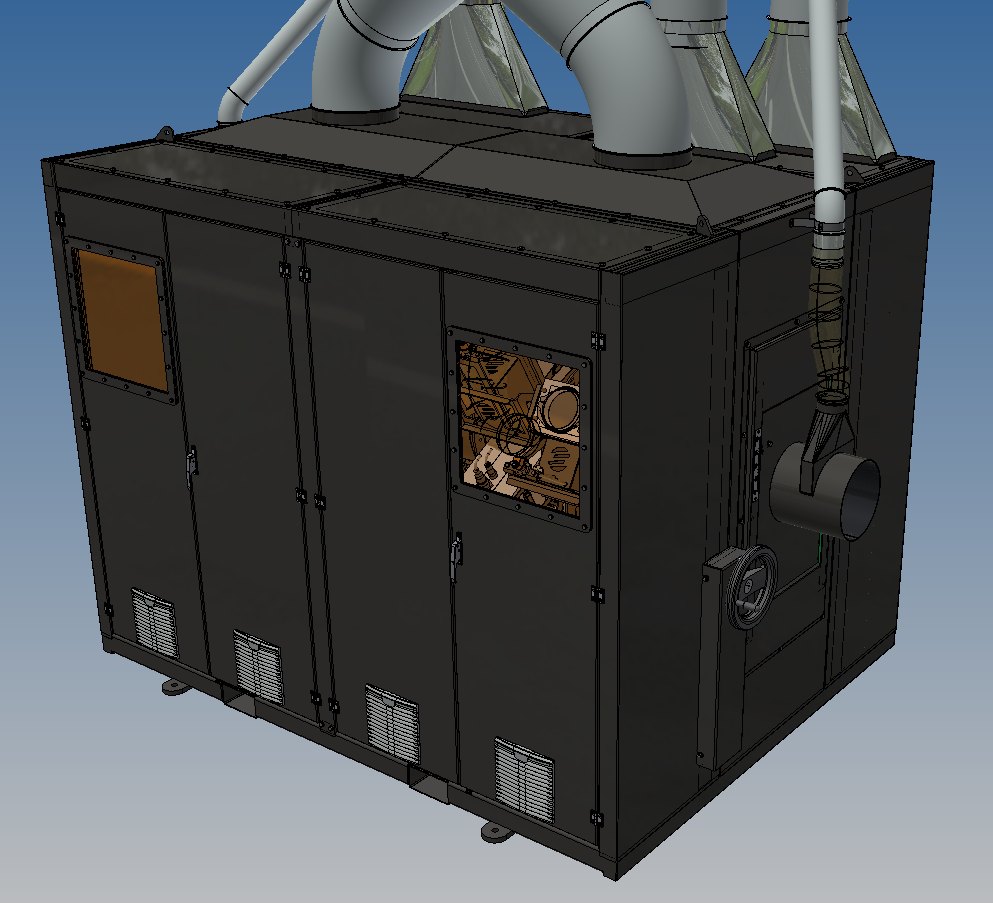

Selmers is convinced that the best results are achieved in mutual cooperation with our clients. After getting acquainted, we prefer to take the time to understand the needs of our clients and the goals they would like to achieve. Based on this we offer a non-binding concept which is open for further discussion and can be fine-tuned into a tailor-made robotic process solution.

Since it is Selmers’ goal to unburden its clients, our care does not stop after successfully commissioning a robotics solution. We provide care during the entire lifetime of the equipment. Which means i.a. that we offer a range of operator trainings and have a 24/7 helpdesk available at your disposal.

The Full Scope:

Focus on innovative and pragmatic engineering

Tailor-made solution using state-of-the-art technology

Process integration

Services where the needs of the customer have the highest priority

More than 50 years experience in creating pipe related process solutions