Selmers’ new Extruder outperforms Verstappen!

Successfully managing the tasks of coating pipes, tubes and monopiles, demands precise execution, paired with substantial power. Our newly upgraded Extruder for coating applications accomplishes precisely that. Boasting a power range that rivals that of a Formula 1 racing car! Pipes are typically first cleaned after which three or more layers of coating are […]

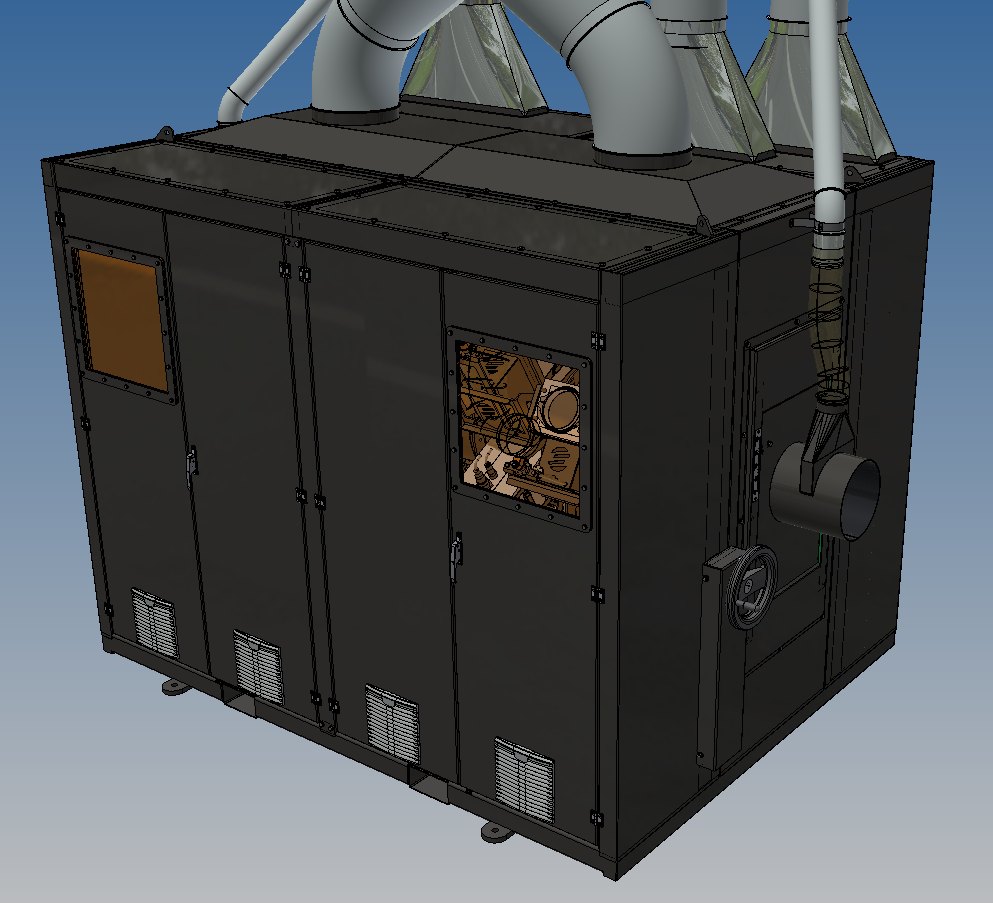

HOT – UV Coating without heat!

HOT – UV Coating without Heat! UV coatings have recently garnered significant attention within the industrial sector. Selmers has therefore decided to integrate UV coatings for tubes into our offerings. This technology represents a new market avenue for us and underscores our commitment to environmental responsibility and innovation. To remain agile, we have […]

Having a blast – actually not coating anything

Having a blast – actually not coating anything Our sales department often receives enquiries about the types of pipes and tubes we blast, coat, and handle. The answer is straightforward: we provide machinery for blasting, coating, and handling of all long steel objects. But, of course, we don’t do this ourselves, as all our customers […]

The buzzwords ‘Operational Excellence’

The buzzwords ‘Operational Excellence’ Operational excellence is a term widely used in various ways to the point where its original meaning has become diluted. Within the industrial landscape, it can mean almost anything. For Selmers, it entails a combination of actions that lead to measurable cost savings, safety, and increased uptime. From reactive to […]

Affordable pipe production through Digitalisation

ADIPEC’s “The Future of Energy” exhibition in Abu Dhabi from 31 October to 3 November 2022 will focus on three pillars: secure, affordable and sustainable energy. They approached them by organizing the zones by related topic of business innovation, namely: decarbonization, offshore and marine, digitalisation and smart manufacturing . They are all relevant to us […]

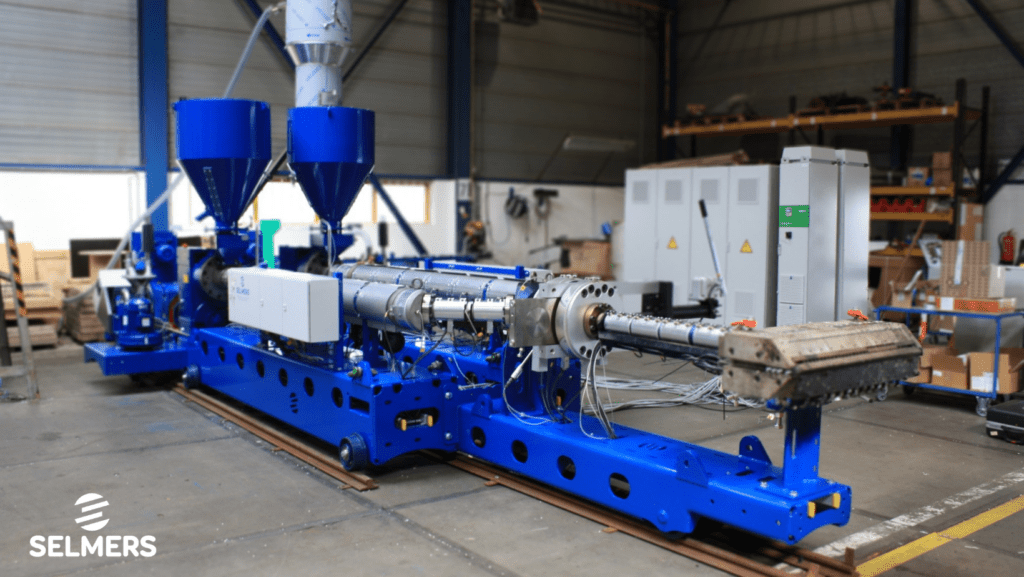

A successful intruder in the world of extruders

Selmers has been supplying equipment for pipe blasting and coating for decades. For the application of an extra layer, or film, to protect this anti-corrosion coating electrically and mechanically, external extruders were used until the mid-1990s. However, those were not sufficiently suitable for our customers’ applications. So what do you do? You develop your own […]

Reaching higher pipe treatment volumes thanks to liquid PU spray

Designing, engineering and delivering equipment for pipe blasting and coating has been one of our specialties for years. Large, small, thick and thin: we have seen it all. Even pipes for water transport no longer hold any secrets for us. At least, that is what we thought. Until some customers came with very specific requirements […]

Pipe Coating Systems (General)

Selmers manufactures pipe coating solutions for various types of coatings, mainly for anti-corrosion, mechanical protection, insulation, flow efficiency and weight increasing purposes. As with individual blasting machines, pipe coating plants are also available for numerous setups: for internal and external applications, small and large diameters, low and high capacities and continuous or one-shift operation. Advantages: […]

PU/PP Foam Insulation Plant

To keep substances in a pipeline at the correct temperature, polyurethane foam (PUF) insulation coating is commonly used for hot oil transmission lines as well as in district heating and cooling. Multi-layer coating with polypropylene (PP) foam providing high thermal insulation; this is used for deepwater pipeline projects. In some cases glass synthetic PP (PP […]

Cement Mortar Lining (CML) Plant

A smooth and compact layer of cement mortar protects water pipes against corrosion and abrasion. How it Works Cement Mortar Lining (CML) is a method for applying a mixture of sand, cement and water onto internal pipe surfaces using a centrifugal spinning or pooring method. A characteristic of CML is that blasting the pipe […]