External Coating System

The Full Scope: FBE powder booth system (single / dual layer) Adhesive powder booth system Coating Extruders (3LPE/PP – 5LPP Foam) Pressure rolling system Weld seam compensation (rolling or injection) Granules supply & drying system Electric control system for extruders Optional: Selmers Plant Management System For more information on this topic contact sales@selmers.com […]

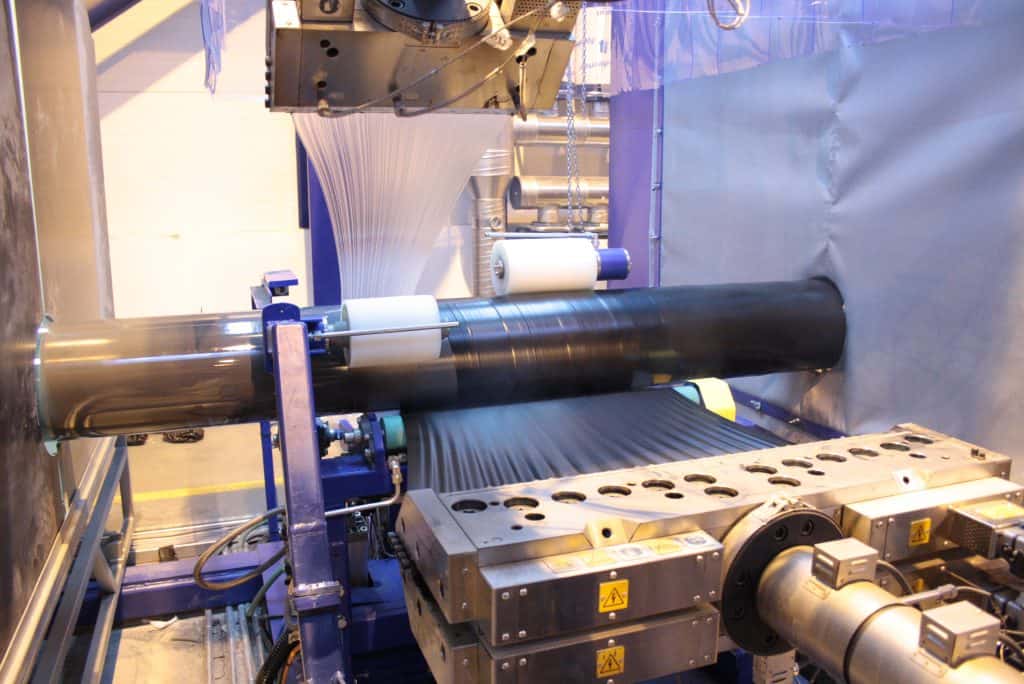

Adhesive Extruder

Produces the adhesive sheets that form the layer in a 3LPE/PP coating. For more information on this topic contact sales@selmers.com This system can also be found as a part of the: External 3LPE/PP-5LPP Foam Pipe Coating Plant

FBE Powder Booth System (single / dual layer)

The Full Scope: Induction Heaters Fluid Beds Epoxy Big Bag Unloaders Hopper HDLV Pumps Epoxy Application Cabin incl. Guns Dust Filter For more information on this topic contact sales@selmers.com This system can also be found as a part of the: External 3LPE/PP-5LPP Foam Pipe Coating Plant

PE or PP Extruder (side & sleeve appl.)

Produces the PE/PP layer used for a protective coating. How it Works Granules of PE/PP are extruded onto the passing pipe, forming a solid coating layer. Side extrusion is most commonly used, where a sheet of PE/PP is wrapped around a pipe. For smaller diameter pipes, so-called sleeve/ring extrusion is a common process. For […]

Internal FBE Coating System

An internal FBE coating is used to protect the inner surfaces of steel pipes from the influence of corrosion and light mechanical impacts and it provides excellent resistance to cathodic disbondment. How it Works The internal Fusion Bonded Epoxy (FBE) system is based on an epoxy powder spray system, mounted on a lance. The […]

Internal Liquid Epoxy / PU & Flow Lining

Internal liquid lining is a coating layer on an internal pipe surface to protect against corrosion or to optimize flow efficiency. There are multiple coating types available such as liquid epoxy, polyurethane (PU), or 2-component coating. How it Works After placing the pipe in the internal liquid coating station, the pipe ends are sealed […]

Field Joint (FJ) Infilller

For more information on this topic contact sales@selmers.com

Field Joint (FJ) Coater

For more information on this topic contact sales@selmers.com

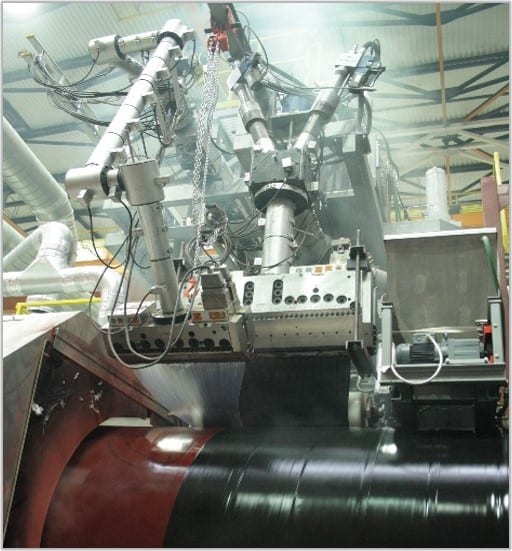

Weld Seam Compensator

The weld seam compensation system (WSC) can be used to increase the amount of coating material on top of the longitudinal weld seam during application of the PE/PP-layer in a side extrusion pipe coating process. The system operates fully automated and can be integrated in new as well in existing (non-Selmers) extruders. Advantages: Overall top […]

Robotic Process Solutions (General)

Nowadays robotics is an essential component in many modern manufacturing environments. They enable production processes to be faster, flexible, safer and more reliable. Selmers believes that each production facility, big or small, can benefit from the advantages of robotic process solutions. Selmers has developed a range of robotic solutions which are valuable for the pipe […]