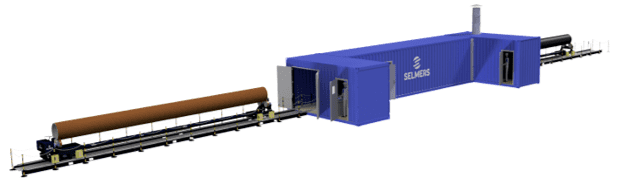

Selmers manufactures pipe coating solutions for various types of coatings, mainly for anti-corrosion, mechanical protection, insulation, flow efficiency and weight increasing purposes. As with individual blasting machines, pipe coating plants are also available for numerous setups: for internal and external applications, small and large diameters, low and high capacities and continuous or one-shift operation.

Advantages:

Flexibility and ease of operation

Sufficient opportunities to incorporate future plant expansion

Easy plant foundation

Quick changeover times to other diameters

Continuous coating results

High accuracy equipment resulting in savings on coating materials

How it Works

All equipment is tailor made to custom specifications. The design of Selmers’ pipe coating systems is flexible in setup and allows for a variety of equipment configurations, depending on the type of operation, type of coating, coating specifications, ambient temperatures and space available.

The Full Scope:

Shot blasting:

- side extrusion,

- cross head die (ring) extrusion

- sintering

Bitumen / Coal tar enamel coating

Internal and external powder (FBE) epoxy, liquid epoxy & PU and PE coatings

Foam (PU) insulation spraying, pouring or injection systems

Deep water (5LPP foam) insulation coatings

Coating of fittings, tees, valves and bends