Selmers’ new Extruder outperforms Verstappen!

Successfully managing the tasks of coating pipes, tubes and monopiles, demands precise execution, paired with substantial power. Our newly upgraded Extruder for coating applications accomplishes precisely that. Boasting a power range that rivals that of a Formula 1 racing car! Pipes are typically first cleaned after which three or more layers of coating are […]

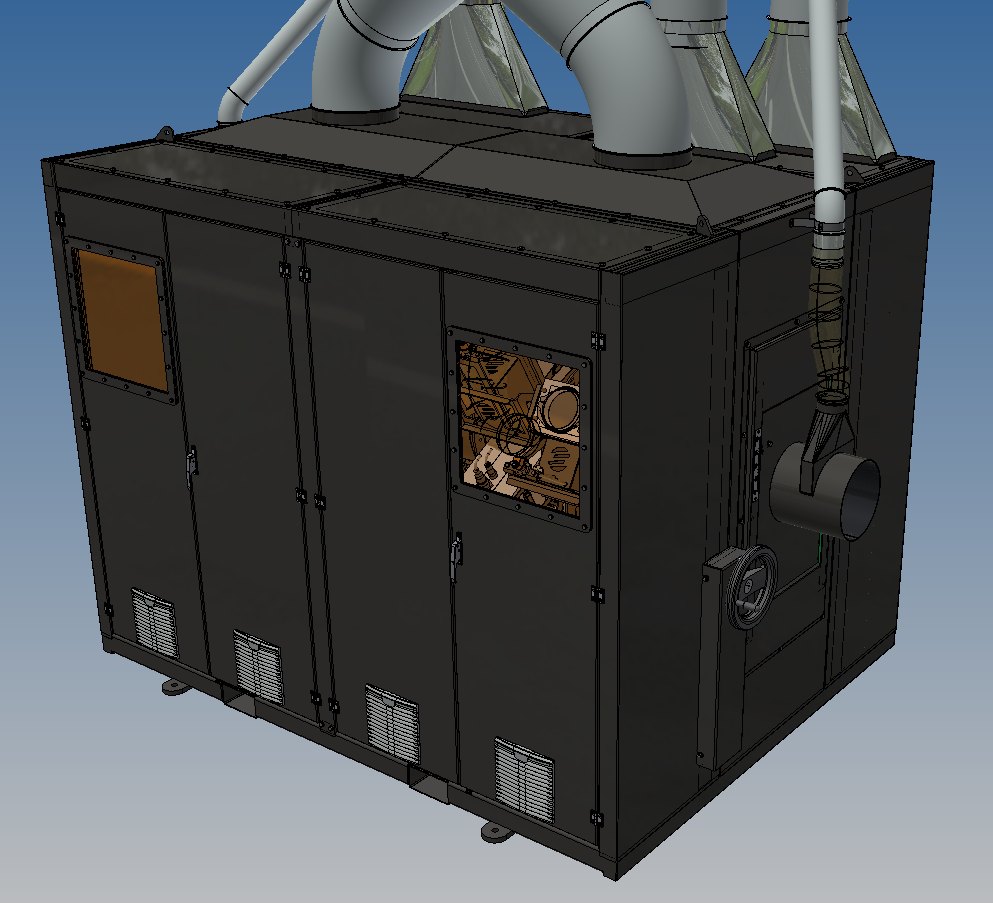

HOT – UV Coating without heat!

HOT – UV Coating without Heat! UV coatings have recently garnered significant attention within the industrial sector. Selmers has therefore decided to integrate UV coatings for tubes into our offerings. This technology represents a new market avenue for us and underscores our commitment to environmental responsibility and innovation. To remain agile, we have […]

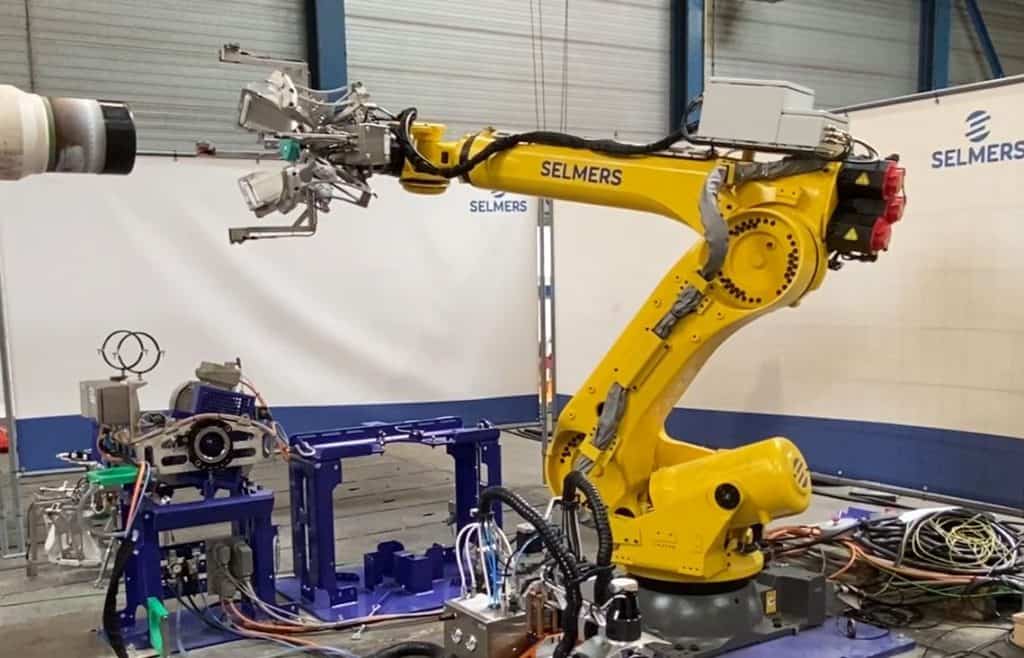

Robots are taking over the (pipe) world

Robots are taking over the (pipe) world When robots were first portrayed in movies such as War of the Worlds and Star Wars, they evoked a primal fear that someday machines and robots would take over the world. However, now that robots are actually here, it appears that we fear not being overpowered, but rather […]

Solving a bouncing problem with determination and grit

Solving a bouncing problem with determination and grit New paint requires a clean surface. The bigger the surface, the better the adhesion of the applied coating. For this purpose, blasting abrasion of pipes is done with grit. The grit is applied with force, and therefore naturally produces some excess grit. One of our clients […]

Longer lifespan, less downtime because of ‘magic touch’

‘Magic touch’ for longer lifespan and less downtime Decades of experience is not something that can be acquired by training, or that can be replaced by equipment. It’s like a person recognising a type of car just by hearing its engine. Or a baker no longer needing his recipes when adding ingredients. Our technical inspectors […]

Offshore ‘Predator’ has eyes on other industries

Offshore ‘Predator’ has eyes on other industries Ever seen a robot on a seagoing vessel? Robots are made of steel which is in essence not best friends with salt and water. Harsh conditions are one of the few certainties at sea. Therefore, most manufacturers of robots take a restraint approach to creating automated solutions for […]

Trick or treat? Unplanned downtime:

a real-life horror story

It is normal for kids to love a scary Halloween. They want to explore the boundaries of their own fears: a way to learn about them. We also like to push our process and equipment for the best results and learn from it. In Operations the focus is often on capacity(output). The adrenaline rushes through […]

The evolution of quality: goodbye to ‘50 shades of grey’

‘Measuring is knowing’ and that is only positive. As management you can steer on data, you can increase your OEE on the production floor and even win a grand prix with it. Also in the field of quality more and more things are measured and made visible in figures and graphs. Smoothing out rough edges […]

What about the Industry4 people:

Ir. Operator? MSc Technician?

Some interesting trends were spotted at TechniShow by our man Jan Peter Biersteker. The next step towards smart industry was the theme of the show and as its name suggest it was all about the technology. So, for us an amazing visit! But the trends give food for thought as well.. Production process: does it […]

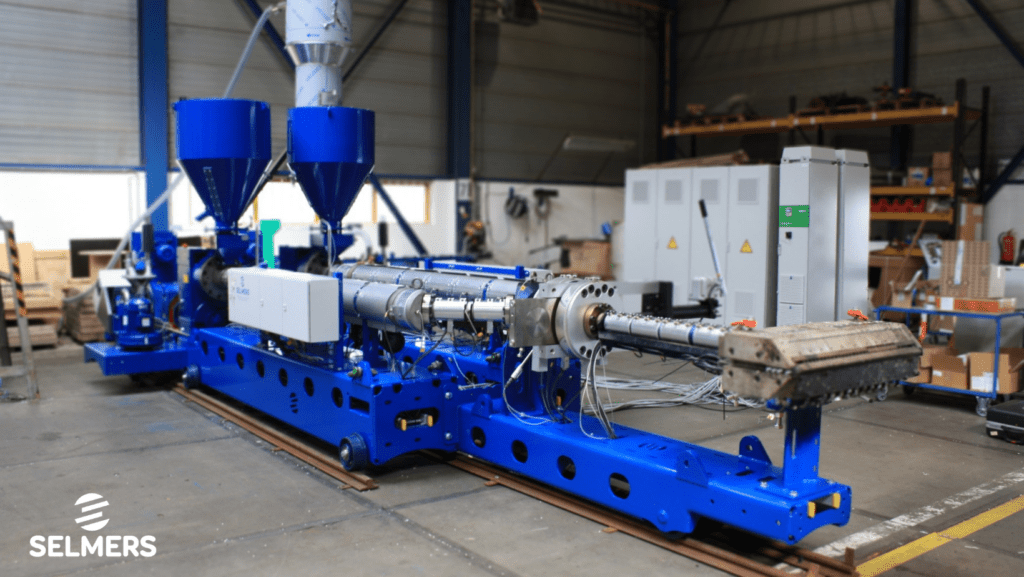

A successful intruder in the world of extruders

Selmers has been supplying equipment for pipe blasting and coating for decades. For the application of an extra layer, or film, to protect this anti-corrosion coating electrically and mechanically, external extruders were used until the mid-1990s. However, those were not sufficiently suitable for our customers’ applications. So what do you do? You develop your own […]