Is your industrial safety really up-to-par?

Whether it’s a robot, object handling equipment or an entire coating line; every piece of equipment that leaves our factory complies with the highest quality standards. At the same time, we put a lot of effort into the safety of our equipment. Conversely, we do not have the full guarantee that customers always work as […]

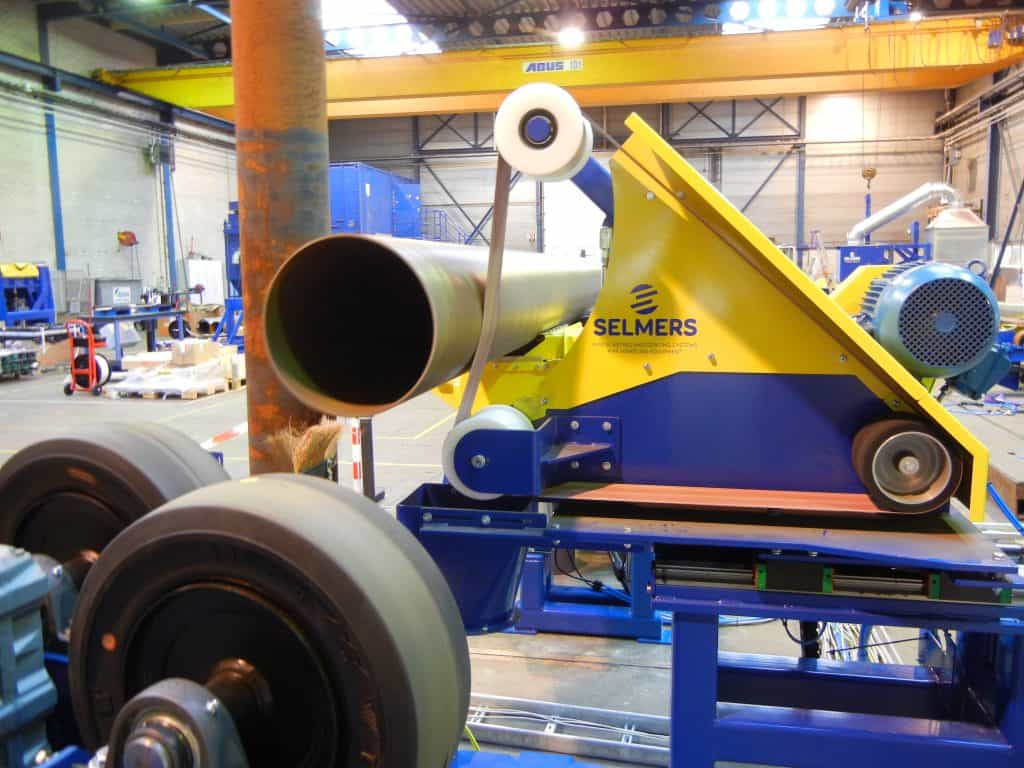

Pipe Handling Systems (General)

To put our machinery to work on the pipes, we first need to transfer the pipes to the machinery. Our wide range of pipe transport equipment offers every solution in efficient plant arrangement while making optimal use of the available space. Advantages: Compact and clever floorspace utilisation Electrically or hydraulically driven High level of automation […]

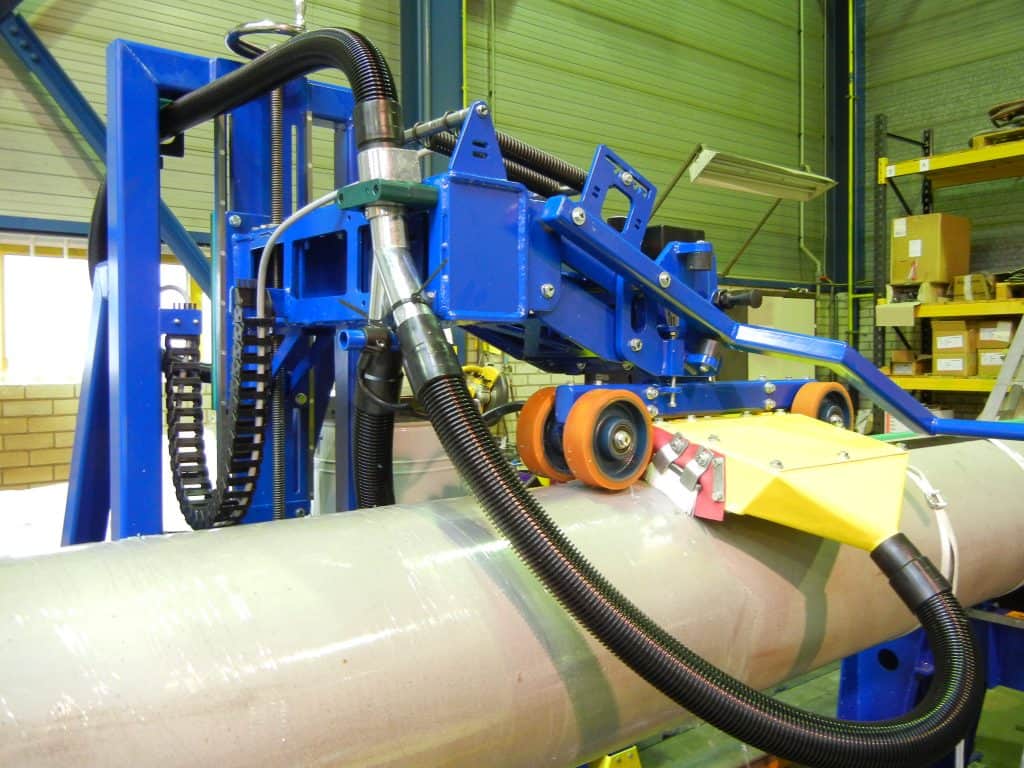

Pipe Cleaning Systems (General)

Selmers recognizes that the cleaning process has a huge impact on the coating quality, so we are constantly striving to perfect the process. Advantages: Proven track record in factories maintaining the highest quality standards Reliable equipment Efficient to use Built to enhance the pipe coating process How it Works As part of the cleaning […]

Indentation Tester

The indentation hardness tester is designed for testing the resistance of the coating to the indentation of an indentor. Advantages: The test equipment is designed according DIN 30670 and DIN 30678 Prepared to perform up to 5 tests Easy way to measure indentation of PE/PP with maximum sample dimension of 100 x 100 mm […]

Brushing Unit

For more information on this topic contact sales@selmers.com

Sanding Unit

For more information on this topic contact sales@selmers.com

Pipe Couplings Monorail System

For more information on this topic contact sales@selmers.com

Mohawk Removal Unit

In the case of a coating mohawk we have a solution to remove the mohawk for a smooth and equalized surface. For more information on this topic contact sales@selmers.com This system can also be found as a part of the: External Blasting &Coating Plant

Infrared Heater

For more information on this topic contact sales@selmers.com

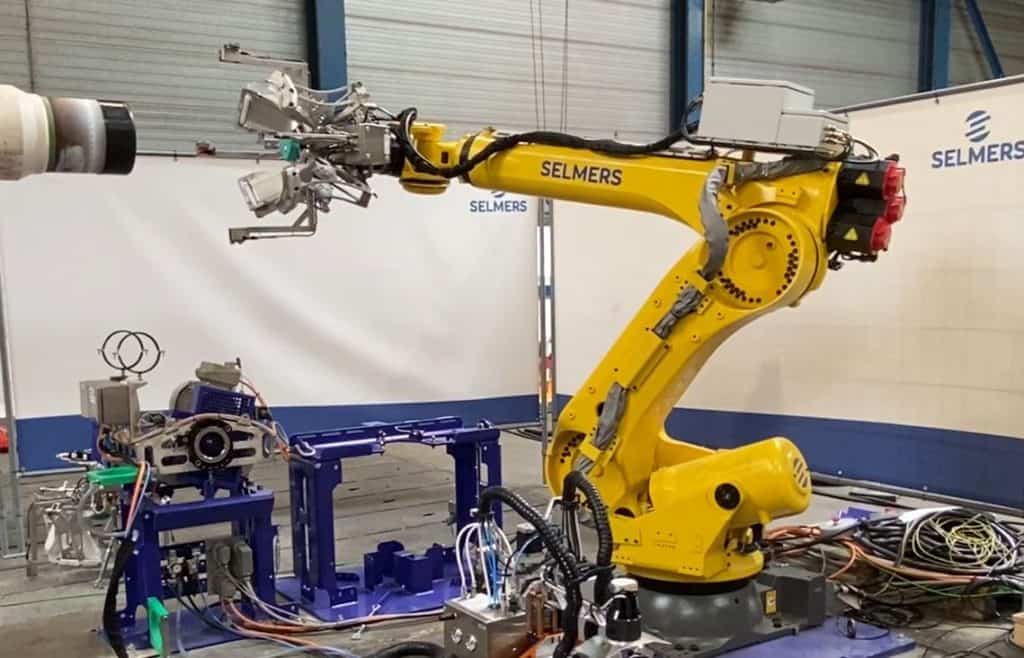

Robotic Pipe End Brushing and OOR (“The Predator”)

This solution was developed in close cooperation with a customer. They process countless individual pipes off-shore into one long pipeline that is then sunk onto the seabed. Before the pipes can be welded together in the so-called prep area on a ship, the end caps must be removed. After that, the surface is treated in […]