Digital Twin Solutions (General)

The next generation of engineering: We have optimized the design processes of our industrial automation into an efficient design street. All this from one database. This improves the qualitative functional designs and knowledge and quality assurance all secured within our PDM. It allows our engineers to focus on our technological innovation preparing you for the […]

Selmers Plant Management System (SPMS)

World’s Digital Demand New economic challenges in the era of global economy are transforming the process industrial environment. Integration of processes, people and organizations is necessary to build on the strengths of each one and optimize performance. Processing plants are facing global competition, environmental regulations, increasing energy costs and tighter product specifications, and still aiming […]

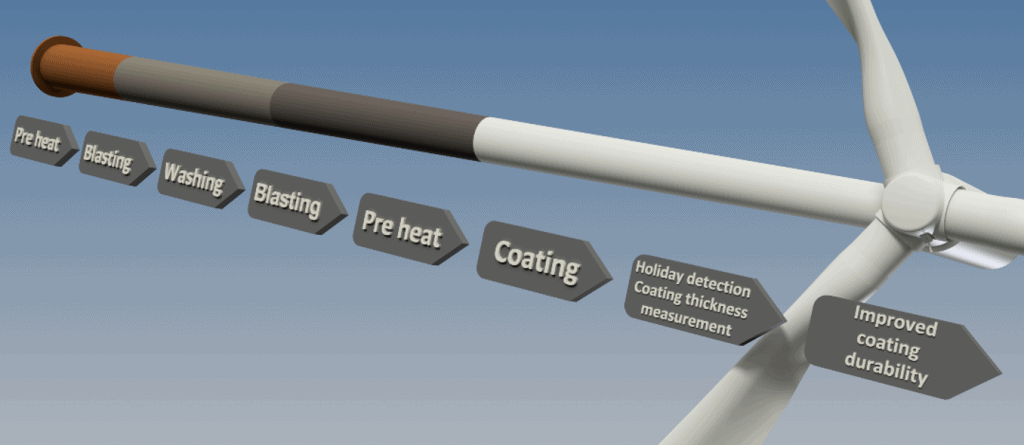

Wind Tower / Monopile Coating Plant

Producers for wind turbines generally use a manual blasting and coating process. Selmers automates this process with a proven system, which increases the capacity, lowers the overall cost and improves the service life of a wind tower or monopile. A Selmers Wind Tower Coating Plant automatically pre-heats, blasts, washes and coats wind towers and monopiles […]

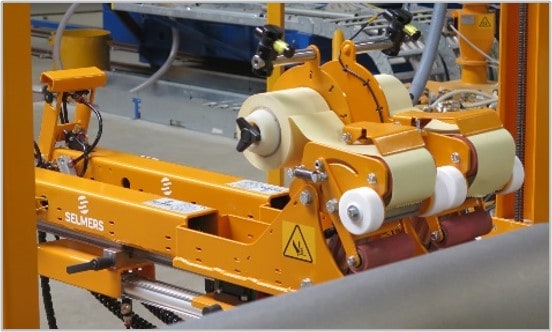

Tape Applicator

The Tape Application unit can be used to protect the pipe cutback with tape in a (spiral) coating conveyor. This system is developed in order to increase the safety level within the pipe coating area and to achieve a better result for cutback coating removal. With the pipe ends taped, the applied pipe coating can […]

Robotic Pipe End Measurement System

Selmers Robotic Pipe End Measurement System (PEMS) automatically measures pipe bevel geometry and out of roundness at the pipe ends. The system produces a dimensional inspection report containing critical dimension and stores these to preferred storage media. Every measurement report can contain up to 360 dimensions for inner radius, outer radius, out of roundness, wall […]

Robotic Internal & External Marking System

The robotic marking system enables flexible pipe marking in pipe coating facilities. The system can function completely autonomous. With the use of pipe position measurement the robot automatically adjusts to different pipe diameters. Depending on the client’s requirement, the marking can be applied inside or outside the pipe as well as axial and radial. Advantages: […]

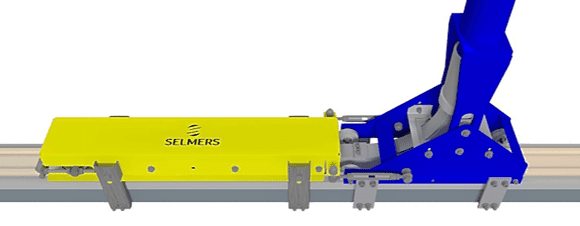

Robotic Blasting System

Robotic blasting systems bring a new level of automation to the joint blasting process. By combining a closed loop vacuum blast system with a robot, a clean process with a continuous and even blast result is achieved. The system automatically detects the cutback area and pipe diameter. Based on this, it determines the path for […]

Portable Tower Coating Repair System

The Portable Tower Coating Repair System is a multi-purpose portable wind turbine maintenance device that can be outfitted with multiple attachments used to inspect, clean, blast, and coat towers for wind turbines. Advantages: Provides a low-cost alternative as compared to conventional repair methods Low mobilization and demobilization costs Quick assembly time Automated systems eliminate the […]

Field Joint (FJ) Coater

For more information on this topic contact sales@selmers.com

Abrasive Acceleration Belt

The Abrasive Acceleration Belt ensures a constant and controlled supply of abrasives during the blasting process, which prevents abrasives from bouncing off the supply belt of the internal blasting system. This new concept is improving the quality of the blasting process, eliminates HSE risks, saves the use of abrasives and extends the lifetime of the […]