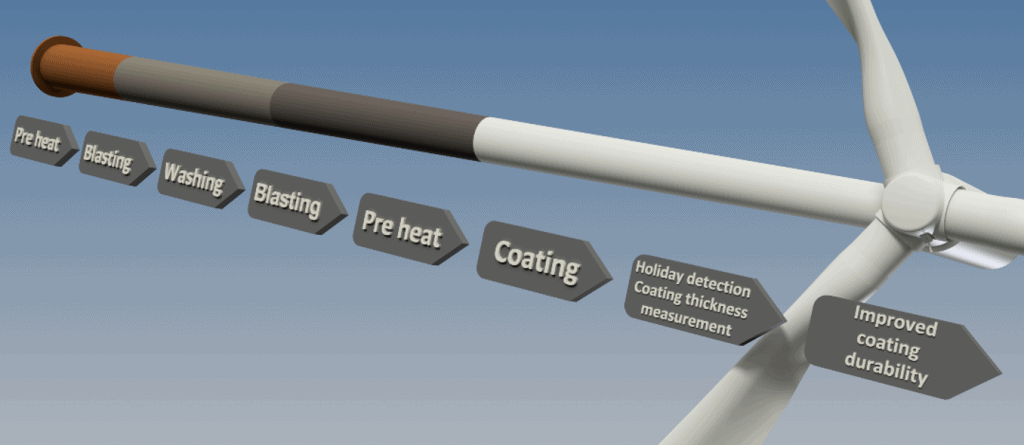

Producers for wind turbines generally use a manual blasting and coating process. Selmers automates this process with a proven system, which increases the capacity, lowers the overall cost and improves the service life of a wind tower or monopile. A Selmers Wind Tower Coating Plant automatically pre-heats, blasts, washes and coats wind towers and monopiles including in-line inspections of holidays and applied coating thickness (QC inspections).

Advantages:

Compliant to all quality standards

Improved capacity and HSE due to high quality turbine blasting.

Cost savings due to automated coating application.

Faster handling and pre-heating for better climatic control, essential for German VGB-S-021 -03;2018.

Constant overall coating performance.

Improved typical service life of coating with less costly repairs.

Reduced cost of ownership for wind park operators.

Reduced overall costs with quick ROI for the coating applicators.

How it Works

Selmers goal for the wind turbine industry is to let you benefit from our comprehensive expertise & excellent track record in automated pipe handling, blasting and coating systems.. Selmers offers a total solution with automated equipment, which upgrades your current blasting and coating process, re-thinks logistics and handling, and creates possibilities for in-line inspections for both wind towers and monopiles.

The Full Scope:

Automatically transporting carriages

(Inductive) pre –heating

High efficient turbine blasting

Cleaning systems

Automated paint application

In-line coating thickness & holiday testing