Robotic blasting systems bring a new level of automation to the joint blasting process. By combining a closed loop vacuum blast system with a robot, a clean process with a continuous and even blast result is achieved. The system automatically detects the cutback area and pipe diameter. Based on this, it determines the path for the blast head.

Advantages:

Minimized abrasive spillage due to excellent alignment of the blasting nozzle

Increased level of safety

Constant quality of blast result

Maintenance friendly blast system

Autonomous system, no need for settings or adjustments by personnel

Automatic adjustment to differences in pipe diameters

Automatic recognition of blast and weld area’s

Simple to operate – no robotics expertise required!

How it Works

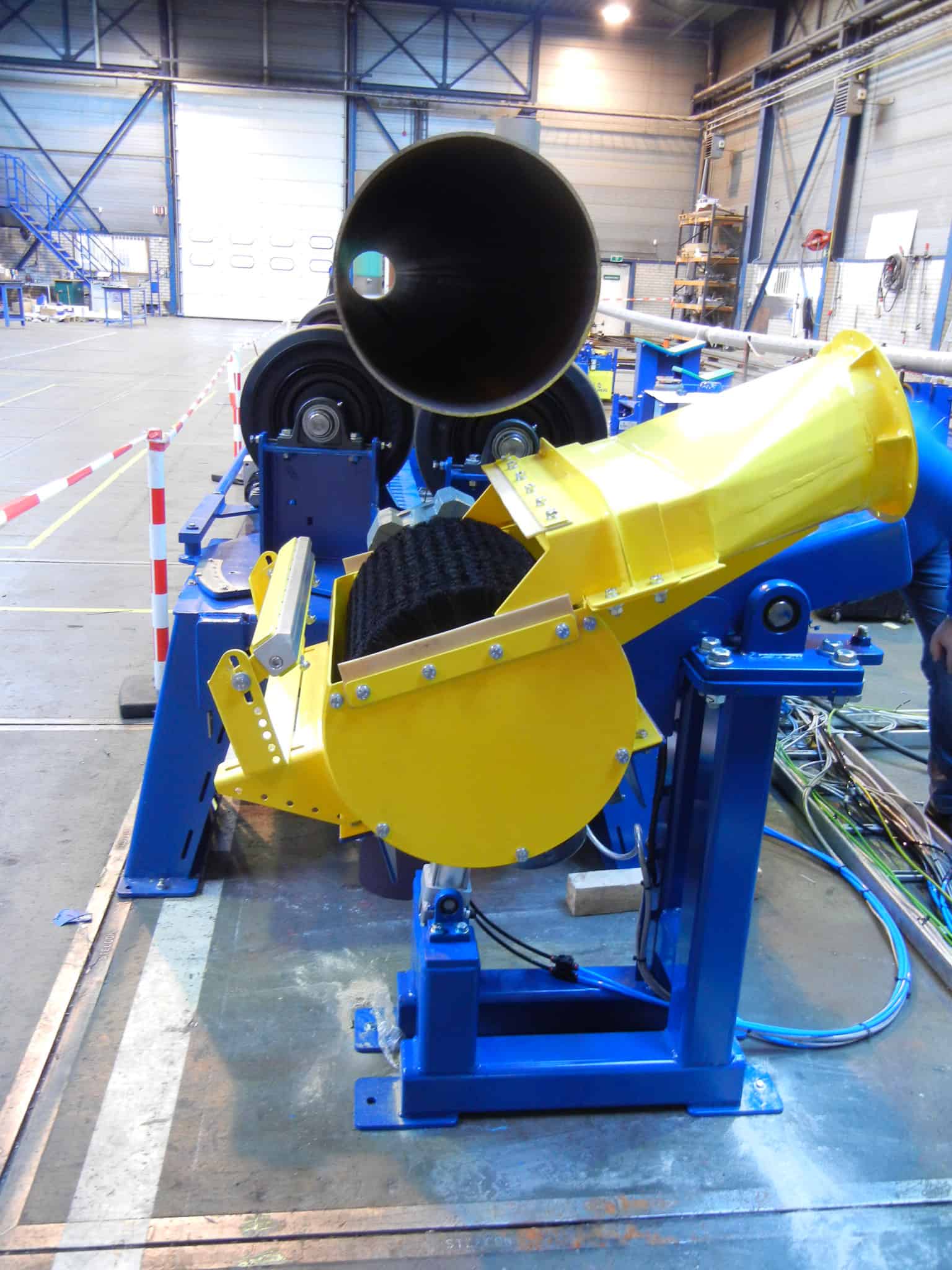

Depending on the process requirement one ore two robots are placed next to the pipe which will be processed and are equipped with a (unique) end of arm tool. This end of arm tool contains displacement measurement sensors and the blast head which is connected to a closed loop vacuum blast system. Sensors will determine the position of the blast area and diameter of the pipe. After the robot(s) having processed this data, the blasting cycle commences. In case a two robot configuration, each robot will blast one half of the pipe.

The Full Scope:

Robot with end of arm tool

Secured work environment

Brush wear compensator

Closed loop vacuum blast system with reclaim system