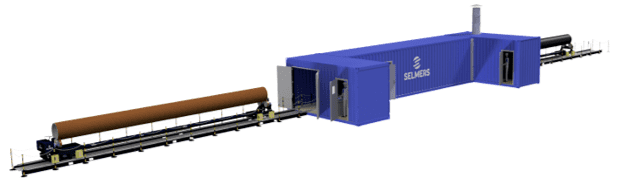

The Portable Tower Coating Repair System is a multi-purpose portable wind turbine maintenance device that can be outfitted with multiple attachments used to inspect, clean, blast, and coat towers for wind turbines.

Advantages:

Provides a low-cost alternative as compared to conventional repair methods

Low mobilization and demobilization costs

Quick assembly time

Automated systems eliminate the potential for human error

Safe maintenance operations in sustained wind speeds up to 12 m/s

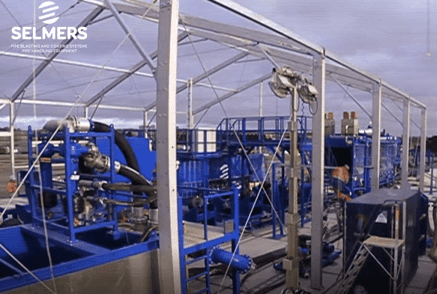

Combines LiftWerx’s innovative up-tower lifting technology with Selmers’ comprehensive expertise and excellent track record in pipe handling, blasting, and coating systems

Liftwerx

LiftWerx specializes in the design, build and operation of alternative up-tower lifting solutions for wind turbine corrective repairs. This new technology is safe, reliable, and is less costly than mobilizing large conventional cranes. In addition to lowering O&M costs, LiftWerx’s up-tower lifting technology reduces ground preparation, and increases the working window to perform maintenance activities by allowing safe operation in wind speeds up to 12 meters per second with gusts up to 18 meters per second.

*Both Selmers and Liftwerx are members of the Meemaken Group of Companies.

How it Works

Designed using lightweight materials, the Portable Tower Coating Repair System is a self-stabilizing device which has the ability to automatically adjust to the various tower diameters. This innovative system creates a stable support platform around the tower, allowing for the adjustment to a wide range of tower diameters. Up-tower lifting technology, designed and provided by LiftWerx, is used to lift the system to the desired heights during operation. This cost-effective technique avoids the high price and disruption of utilizing larger conventional cranes or aerial lifts on the ground. This method also avoids the inconvenience of drilling holes in the nacelle wall in order to accommodate rope-access methods.