Internal Blasting System

In the internal mechanical blasting process the pipe surface is blast cleaned with dry-grit using a blast boom system. A highly concentrated stream of steel abrasive particles are projected at the surface. The goal is to remove rust, mill scale and contaminations in order to create the correct cleanness and surface roughness profile, beneficial for coating adhesion. […]

Field Joint (FJ) Blaster

Spread all over the world, a lot of different types of Selmers pipe blasters work successfully; for external and internal pipe coating plants, field joint blasters suitable for S-lay & J-lay vessels, for spoolbases or cross-country usage. Selmers has designed for onshore pipeline construction or spoolbases, a standard program of field joint blasters in 3 […]

Robotic Process Solutions (General)

Nowadays robotics is an essential component in many modern manufacturing environments. They enable production processes to be faster, flexible, safer and more reliable. Selmers believes that each production facility, big or small, can benefit from the advantages of robotic process solutions. Selmers has developed a range of robotic solutions which are valuable for the pipe […]

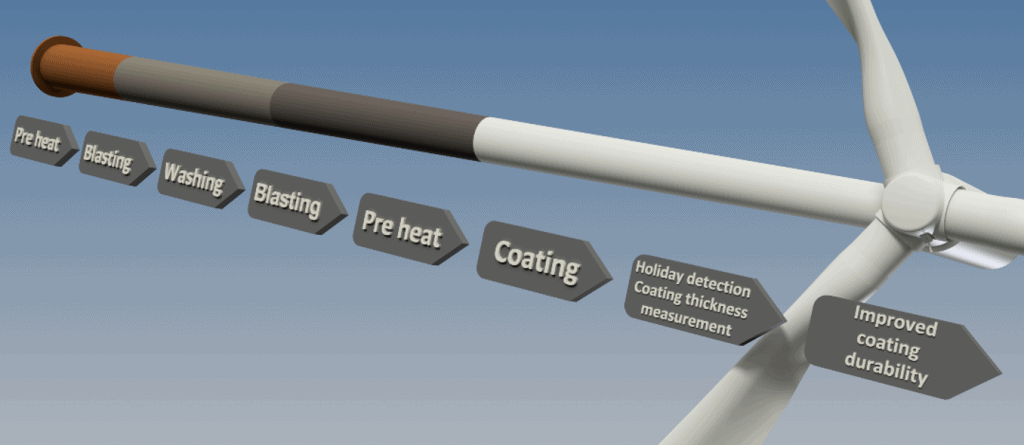

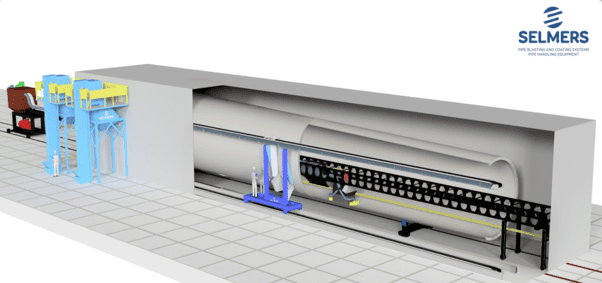

Wind Tower / Monopile Coating Plant

Producers for wind turbines generally use a manual blasting and coating process. Selmers automates this process with a proven system, which increases the capacity, lowers the overall cost and improves the service life of a wind tower or monopile. A Selmers Wind Tower Coating Plant automatically pre-heats, blasts, washes and coats wind towers and monopiles […]

Wind Tower Blast System

The Wind Tower Blast System is designed to blast wind tower cones automatically and mechanically, all with the purpose to remove rust and contaminations and create a correct surface roughness for further treatment. Advantages: Quick Return on Investment (ROI) Cost reduction: low labour, low energy and low consumption of abr Minimum production time, internal and […]

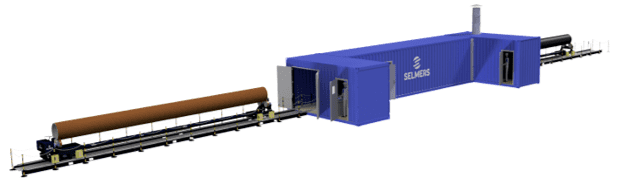

Transportable Blast & Coat System

The transportable blast and coat system is designed for external blasting and coating of steel pipes. This process is normally done by high investment machines with a long changeover time when it comes to switching pipe diameters. Such machines are designed to process large batches of pipes. Selmers is able to offer a system having […]

Robotic Blasting System

Robotic blasting systems bring a new level of automation to the joint blasting process. By combining a closed loop vacuum blast system with a robot, a clean process with a continuous and even blast result is achieved. The system automatically detects the cutback area and pipe diameter. Based on this, it determines the path for […]

Portable Tower Coating Repair System

The Portable Tower Coating Repair System is a multi-purpose portable wind turbine maintenance device that can be outfitted with multiple attachments used to inspect, clean, blast, and coat towers for wind turbines. Advantages: Provides a low-cost alternative as compared to conventional repair methods Low mobilization and demobilization costs Quick assembly time Automated systems eliminate the […]

High Performance Blast Wheel℗

In the internal mechanical blasting process the pipe surface is blast cleaned with dry-grit using a blast boom system. A highly concentrated stream of steel abrasive particles are projected at the surface. The goal is to remove rust, mill scale and contaminations in order to create the correct cleanness and surface roughness profile, beneficial for coating adhesion. […]

External Blasting System

In the external blasting process the pipe surface is blasted inside a blast cabin. This with the goal to remove rust, mill-scale and contaminations in order to create a correct cleanness and surface roughness profile for further treatment. Advantages: Flat/shallow floor erection reducing investment in deep pits Rigid manganese steel blast cabin No pipe support […]