Spread all over the world, a lot of different types of Selmers pipe blasters work successfully; for external and internal pipe coating plants, field joint blasters suitable for S-lay & J-lay vessels, for spoolbases or cross-country usage. Selmers has designed for onshore pipeline construction or spoolbases, a standard program of field joint blasters in 3 sizes. The external blasters are of ‘closed loop’ vacuum blasting type with efficient re-use of abrasives.

Advantages:

High blasting capacity

Clean process (minimal abrasive loss)

Operator friendly

Automated and remote controlled process

Low noise level in comparison to manual blasting

Maintenance friendly

Quick return on investment

How it Works

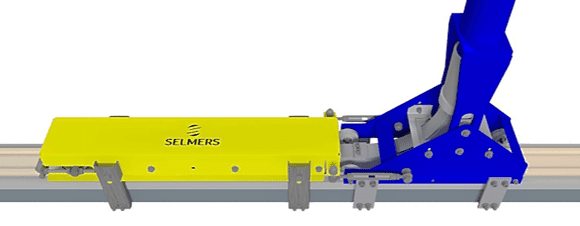

The Field Joint blasters are based on horseshoe shape devices configured for up to four vacuum blast nozzles. The system needs to be placed onto and taken from the joint area by means of e.g. a crawler truck with loader arm. After placement the blaster clamps itself into position. Once the position is secured the joint is blasted. The blast nozzles are paired up, each pair blasts one half of the joint area. To ensure a tight seal of blast nozzles on the pipe, they are equipped with brush seals.

The Full Scope:

Light weight frame

Vacuum blast system with up to four blast nozzles

Abrasive reclaim system

Brush wear compensator