To put our machinery to work on the pipes, we first need to transfer the pipes to the machinery. Our wide range of pipe transport equipment offers every solution in efficient plant arrangement while making optimal use of the available space.

Advantages:

Compact and clever floorspace utilisation

Electrically or hydraulically driven

High level of automation

Eye on safety

How it Works

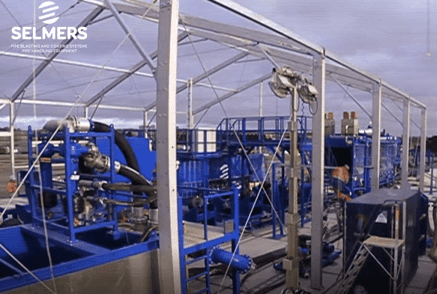

Customers value Selmers because we always think with them. Experience has taught us that each customer has their own preferences when it comes to plant logistics. This demands flexibility. With our range of pipe handling equipment, available in various measurements, we can offer you this flexibility.

The Full Scope:

External Area Pipe Handling Equipment

External pipe treatment generally takes place on moving pipes. Usually pipes are moved on a blasting conveyor or coating conveyor. At the inbound section this typically consists of a combination of pipe racks, stoppers, lower-in / kick-out handlers, pipe indexers, hempel racks or rotation units.

Internal Area Pipe Handling Equipment

A characteristic of an internal pipe blasting and coating plant is that pipes are processed individually in separate stations, linked by pipe transfer systems. This is usually done by pipe indexers, pipe buggies, chain conveyors or walking beams.

Offshore Pipe Handling Equipment

Selmers supplies full deck handling equipment for S-lay and J-lay-barges. The scope consists of V-type support rollers (fixed, liftable or pivot), firing line rollers, line-up tables and transverse conveyors, but also solutions for more complex pipe handling, such as pipe elevators (single or multi-joint), hoisting equipment, adjustable launch tables for work tools, walking beams, indexers and so on.

Spoolbase, Double & Multi Joint Pipe Handling Equipment

At spoolbases, double joint and multi joint facilities fast efficient pipe transport is important to produce pipe strings. To achieve this, Selmers equipment applies various transport principles in modular sizes like diabolo rollers, line-up modules (LUM), chain conveyors, hempel racks, pipe indexers and walking beams.