Introduction:

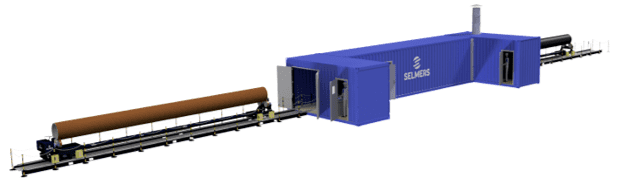

Stalk racks are essential stationary supports in spoolbase facilities, designed to store and secure long sections of welded pipe (stalks) before they are spooled onto reel-lay vessels. These racks ensure efficient handling, protection, and organization of pipeline stalks, streamlining offshore pipeline installation.

Solution:

Stalk racks provide safe and efficient storage for fabricated pipe stalks, protecting them from damage and ensuring smooth handling during the spooling process.

Key Features:

- Robust Support System: Utilizes wooden spacers and wedges to maintain stability.

- Efficient Stalk Handling: Excavators equipped with roller boxes ensure precise positioning.

- Durable Construction: Concrete plinths at rack ends facilitate secure winch operations.

Benefits:

- Maximized Storage Capacity: Optimizes space utilization within spoolbase facilities.

- Heavy-Duty Durability: Built to withstand high loads and harsh environmental conditions.

- Pipe Integrity Protection: Integrated support system prevents damage during storage.

- Seamless Spooling Process: Designed to enable a smooth transition of stalks to and from the spooling line.

- Industry Compatibility: Works with standard pipe-handling equipment used in spoolbases.

- Coastal Resilience: Engineered for long-term durability in marine environments.

- Enhanced Safety: Prevents pipe movement and shifting during storage.

How It Works:

Fabricated pipe stalks are transferred from the firing line to the stalk racks using specialized handling equipment. Each stalk is carefully positioned on the racks using support posts and spacers to prevent contact between pipes. When ready for spooling, the stalks are pulled onto the spooling line with dedicated equipment, such as wheeled loading shovels fitted with custom pipe-pulling attachments.

The Full Scope:

Stalk racks are a critical component of spoolbase operations, enabling the efficient onshore assembly of long pipeline sections. Designed for strength, adaptability, and seamless integration with welding lines and reel-lay vessels, they contribute to faster project execution, improved safety, and cost savings. Their role in offshore pipeline projects makes reel-lay and spoolbase fabrication a preferred choice for modern deepwater installations.

More information?

Be sure to stay ahead in the manufacturing game and join us at the forefront of manufacturing innovation. Whether you need project-specific solutions or comprehensive strategies for your production in the pipe, tube, and profile industry, we’re here to assist. Call +31 (0)251 211 999 or send an email to sales@selmers.com or fill in the contact form.