After a pipe has been coated, pipe end cleaning is necessary to create cutbacks, a clean surface in order to weld the pipe ends to each other to create a pipeline. The first part of a pipe end is assumed to be cleaned, i.e. the part which shall be free from FBE.

Advantages:

High accuracy

Pipe bevel roll to fixate position

Easy adjustable for different pipe diameters

How it Works

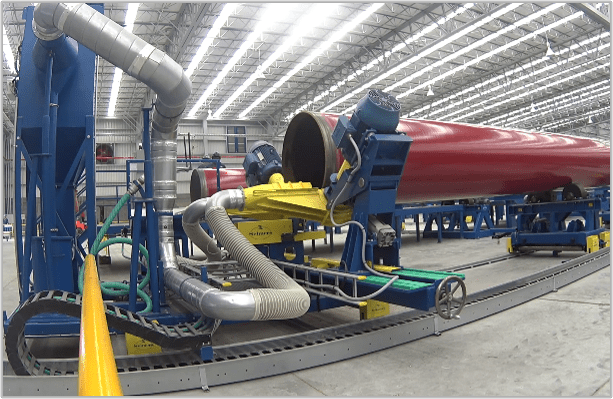

The pipe end brush system cleans the pipe end with a steel brush and removes all of the PE/PP, adhesive and epoxy layer. Pipe end cleaning cars are installed at each pipe end. The carriages are moved towards the pipe ends after which the brushes are pressed against the rotating pipe with a pneumatic cylinder. A dust collector system is used to extract brushed off coating material during brushing.

The Full Scope:

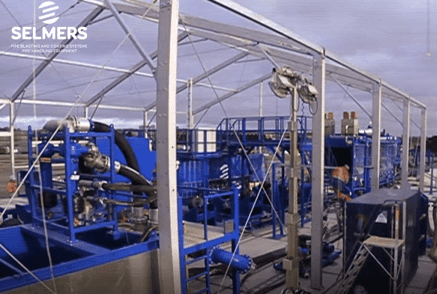

Pipe support and rotation unit

Pipe end brush units

Dust collector system

Electrical control system

Remote control/camera monitoring (option)

Optional:

Remote control/camera monitoring (option)

Noise reduction cabin