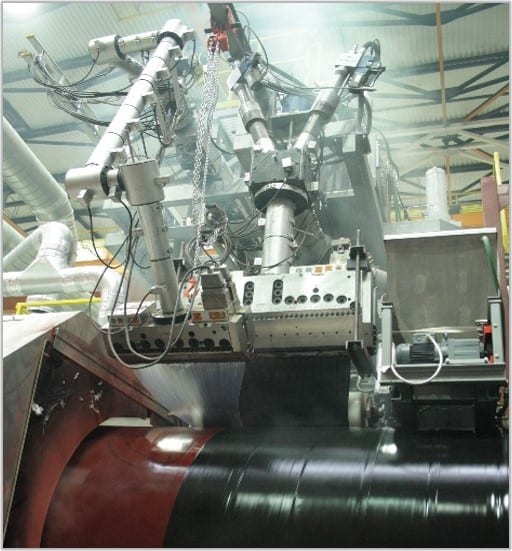

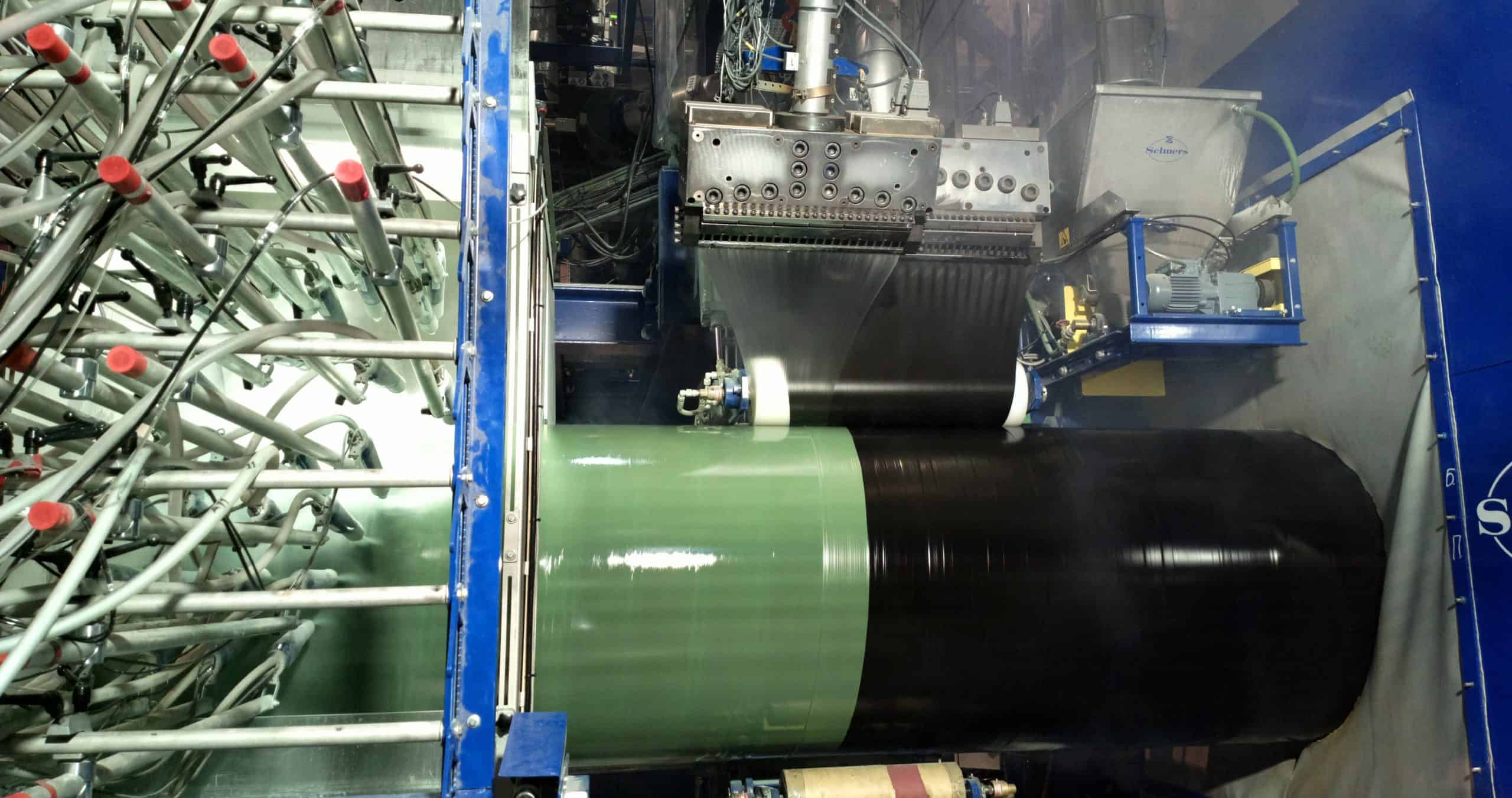

The weld seam compensation system (WSC) can be used to increase the amount of coating material on top of the longitudinal weld seam during application of the PE/PP-layer in a side extrusion pipe coating process. The system operates fully automated and can be integrated in new as well in existing (non-Selmers) extruders.

Advantages:

Overall top layer coating thickness (PE or PP) consumption can be reduced

System can be integrated in a wide range of existing extruders

Highly automated injection system operated by a PLC and weld seam detection sensors

Adjustable settings to cope with a flexible diameter range & capacity

Contactless weld seam detection

Quick ROI due to reduction on coating materials

Double injection possibility

How it Works

With the WSC-system installed between flathead die and PE-screen, the system is been able to diminish the total amount of extruded material, as only an extra amount on the weld is being applied, rather than on the whole pipe. For small diameter pipes, two cylinders can be used alternately to create more filling time.

The Full Scope:

Injection system

Manifold block

HPU

Weld seam detection system

Stand-alone PLC with HMI-operator screen