Introduction

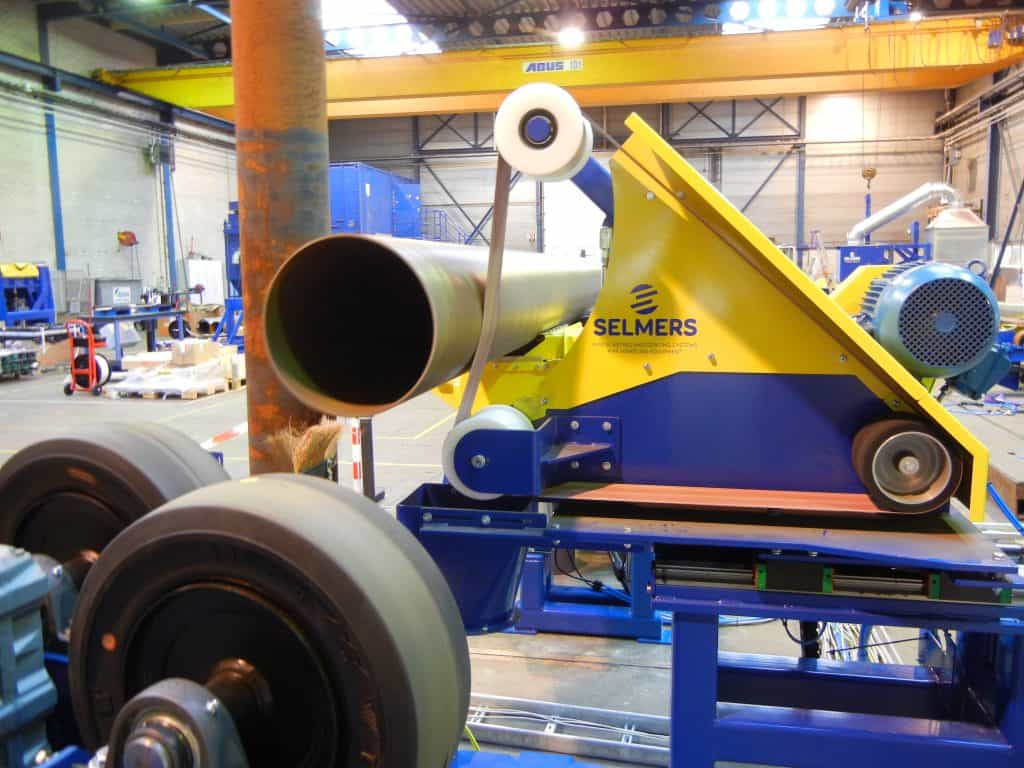

Sanding is essential to prepare coated pipes for additional layers. Our Sanding Unit enlarges the surface area consistently, improving adhesion for subsequent coatings.

Solution

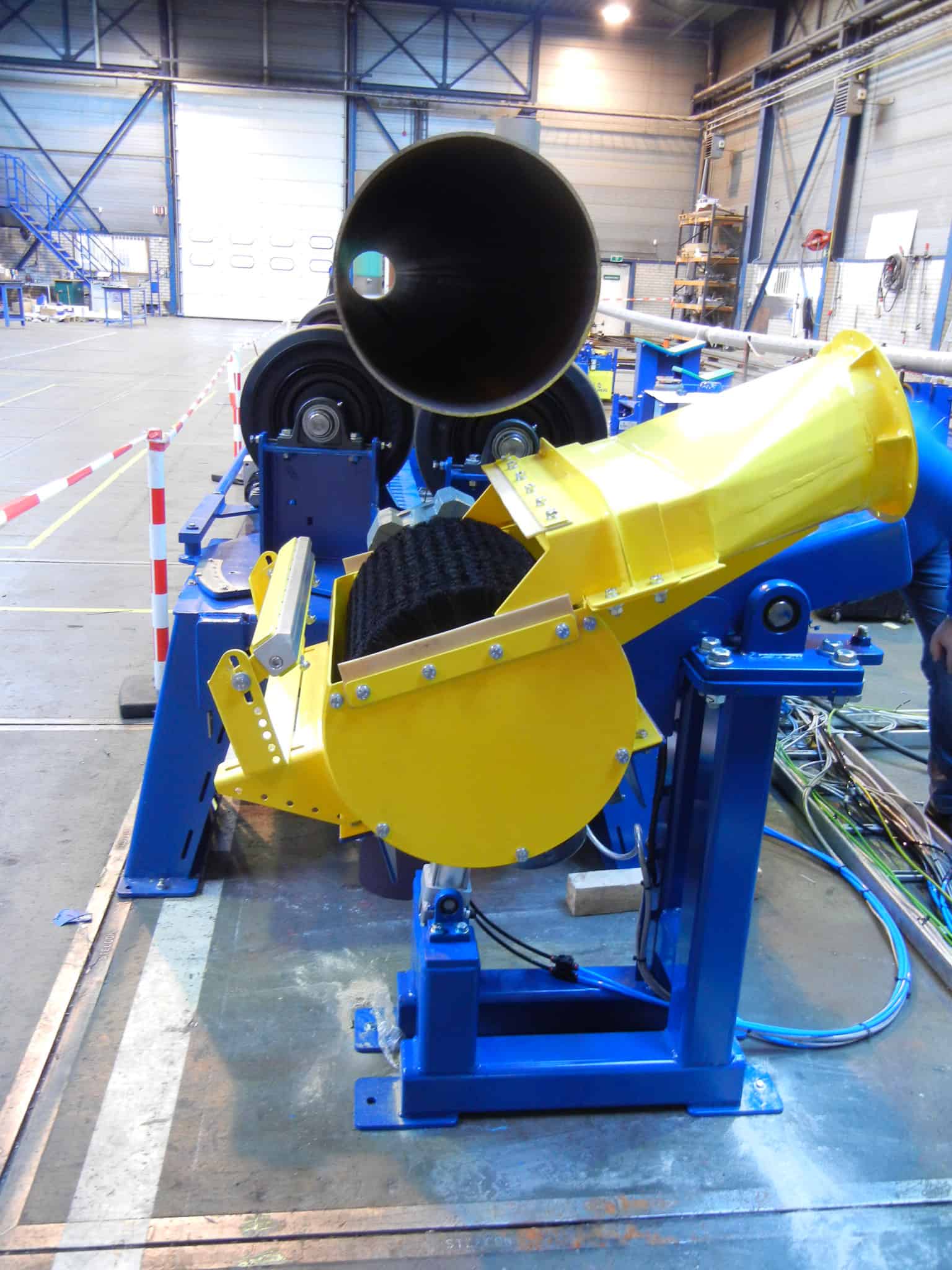

The Sanding Unit uses an abrasive belt to roughen and maximize the surface area of coated pipes. This creates a textured finish that enhances adhesion for additional layers. Common practice is doing this by hand, which leaves too much room for errors in today’s stringent climate for energy networks. This solution is often, but not exclusively used when lateral ground drilling is needed, and pipes are exposed to significant external stresses, requiring them to be highly fortified.

Key features

- Consistently performing abrasive belt.

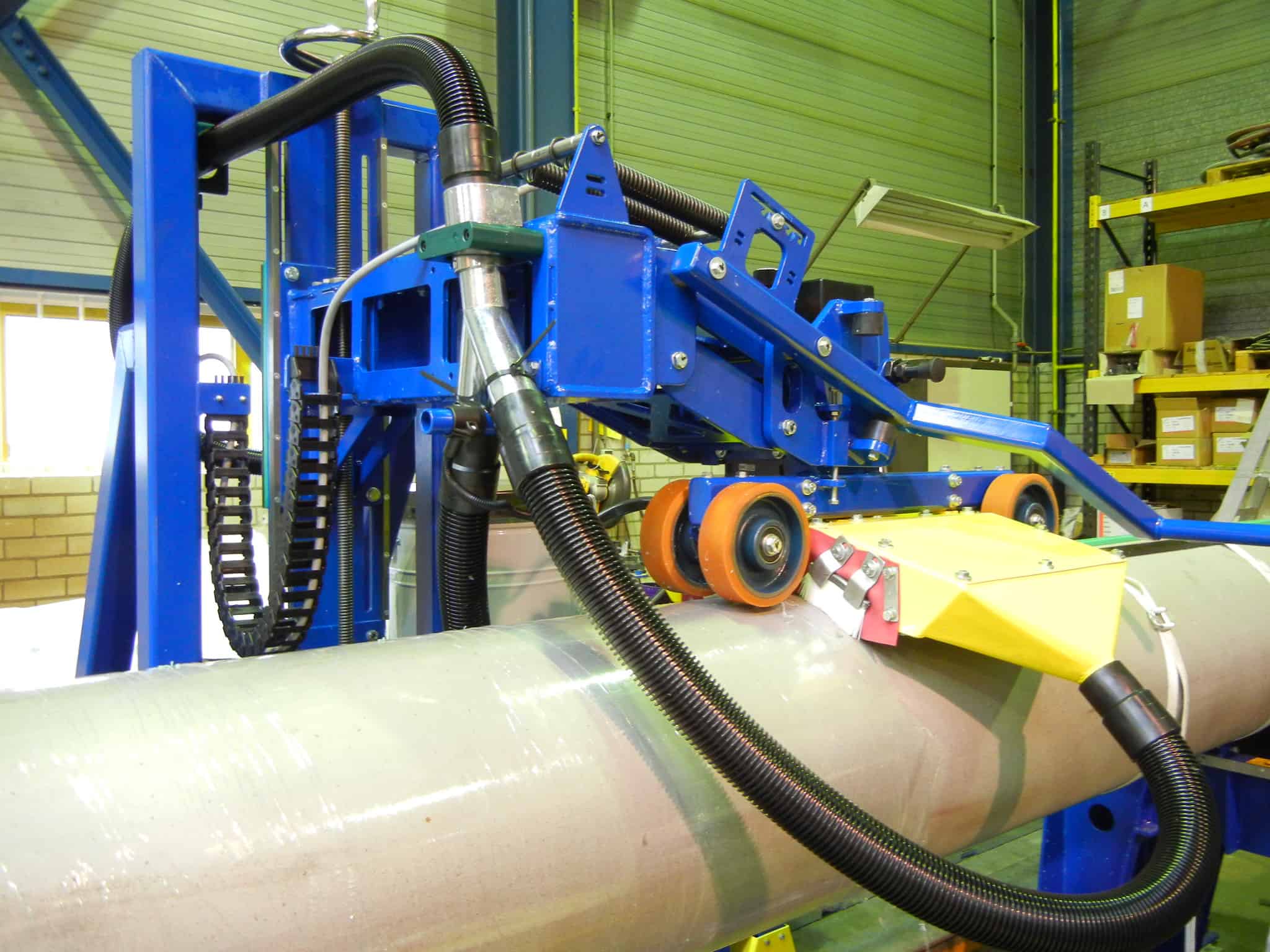

- Adjustable sanding pressure for specific coating needs.

- Suitable for various pipe diameters and all lengths.

- Easy integration with existing coating lines.

- Low maintenance requirements.

Benefits

- Improves adhesion of additional coating layers.

- Enhances coating durability and performance.

- Reduces risk of coating failures.

- Increases efficiency of the coating process.

- Better working conditions for employees.

- More efficient than manual sanding.

- Automates the process, saving time and money.

- Provides better measurable output, conforming to CSRD regulations and legal requirements.

How it works

The unit operates by running an abrasive belt with consistent pressure across the surface of the pipe. This process enlarges the surface area, ensuring optimal roughness for better coating adhesion.

The full scope

- Installation: Designed for seamless integration with existing pipe handling and coating systems.

- Operation: User-friendly controls to adjust sanding pressure and speed based on pipe material and coating requirements.

- Maintenance: Minimal maintenance with durable belts that can be easily replaced when worn.

Product range

Any length, with , diameters up to 20”

More information?

By mutual learning, we have grown to who we are today. A trustworthy supplier of a multitude of automated solutions. Do you want to optimize performance and reduce risks? Send an email to sales@selmers.com or call +31 (0)251 211 999, or fill in a contact form via https://www.selmers.com/contact and we’ll get back to you.