In order to obtain an as clean as possible pipe surface, pipes may be additionally “cleaned” after blasting. In the phosphoric acid wash cleaning process a carefully premixed acid solution is sprayed on the pipe with the goal to remove possible contaminations such as salts (chlorides and sulphates), light oxidation, oil traces, surface dust and/or carbon residues.

Advantages:

Enhanced adhesion of applied coating

Efficient use of consumables

Highly reliable process control

Angled roof to prevent drops on pipe

Fully adjustable cabin for optimal process settings

Optimized design based on long history of successfully functioning acid wash units

How it Works

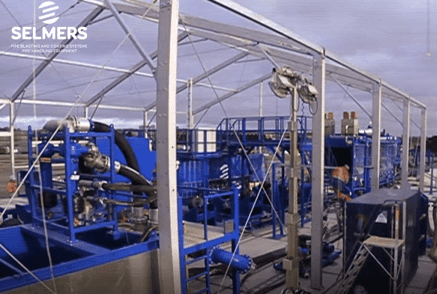

The process typically consists of the acid application step, a certain dwell time interval which is required to let the acid solution do its work and finally a high pressure water rinsing step. The used water shall be free from contaminations avoiding for pollution of the pipe surface and hence shall be demineralized or obtained from a reversed osmosis water supply. The acid solution is prepared on a skid mounted equipment module with special process tanks for mix preparation and ready mix. These process tanks are fitted with level indicators, stirrers and the required electrics and instrumentation.

The Full Scope:

Application cabin

Acid solution preparation skid

High pressure water pump

Waste water treatment system

Extended line speed

Optional:

Reverse osmose unit

Fluorescent lighting

Window flush nozzles

Extended cabin length