This solution was developed in close cooperation with a customer. They process countless individual pipes off-shore into one long pipeline that is then sunk onto the seabed. Before the pipes can be welded together in the so-called prep area on a ship, the end caps must be removed. After that, the surface is treated in preparation of the welding.

Advantages:

Quick change-over from one pipe-end treatment to the other

Safe pipe end surface treatments

Autonomous system, no need for settings or adjustments by personnel

Simple to operate, no robotics expertise required!

How it Works

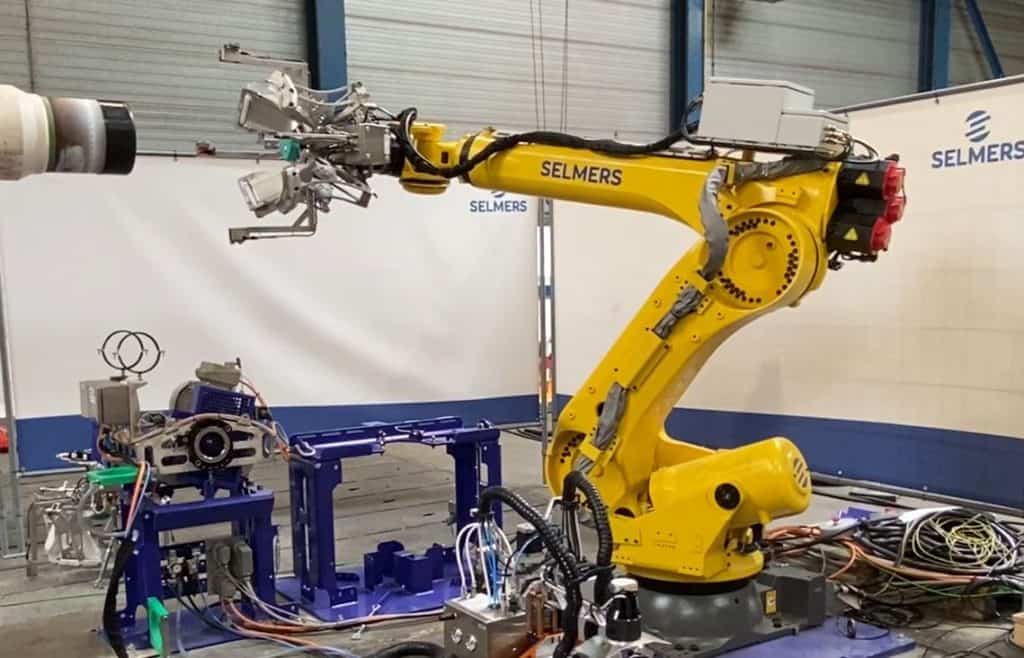

Together we quickly came up with a concept of a robotic arm with a sort of claw attached to it to grip the caps and remove them. From the same position, some twenty seconds later, the robot picks up a brushing machine that cleans the rotating pipe on the outside. Subsequently the next tube is brought into position and both actions are repeated over and over again.

The Full Scope:

Industrial robotic system

Secured work environment