Epoxy powder has outstanding corrosion protection characteristics and is commonly used as a corrosion protection layer in several coating processes, e.g. single layer Fusion Bonded Epoxy (FBE), dual layer FBE, three layer PE/PP coating process, etc.. However, a similar system can also be used as an adhesive powder spray system instead of an extruded adhesive layer.

Advantages:

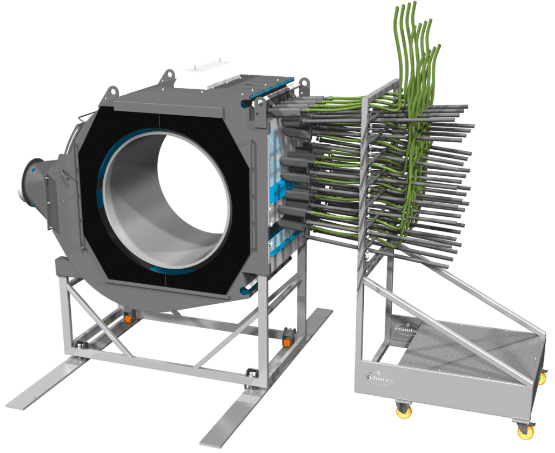

Special rounded cabin design for improved powder transfer efficiency and cleaner cabinet

Powder flow control, i.e. closed loop digital gun control

Selmers’ filter system, anti-clocking and extended life time

Optimized reclaim system for lower consumption of epoxy powder

Automatic fire/explosion suppressing system

Gun slide rack for quick diameter adjustments

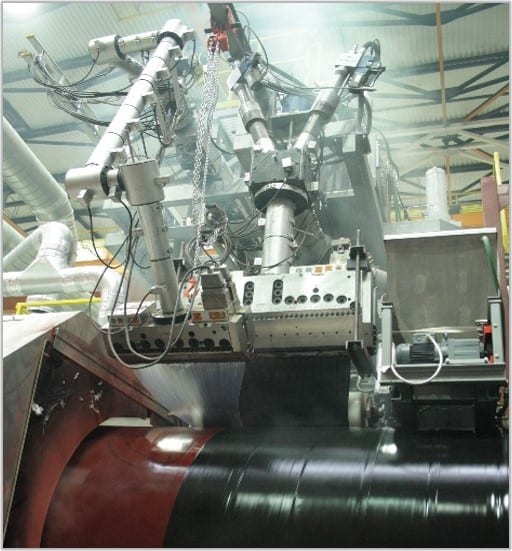

How it Works

The dry epoxy powder is conveyed from a powder hopper to the spray guns by dry and clean compressed air. After the epoxy powder is electrostatically charged, it is sprayed onto the preheated, rotating or linear moving pipe. Under the influence of temperature the applied powder melts and transforms into a cured anti-corrosion layer. Over sprayed powder is recovered and returned to the reclaim powder hopper for recycling. By means of a powder flow control module there is a closed loop digital gun control and up to 250 recipes can be programmed and stored with touch screen panel.

The Full Scope:

Application cabin with cabin seals

Electrostatic FBE guns

Epoxy powder supply system

Reclaim system with dust filter

Rotary sieve

Fire suppression system

Control system

Optional:

Big bag unloader

Cyclone system

Powder weighing system

Adhesive powder application

Rough coat applicator