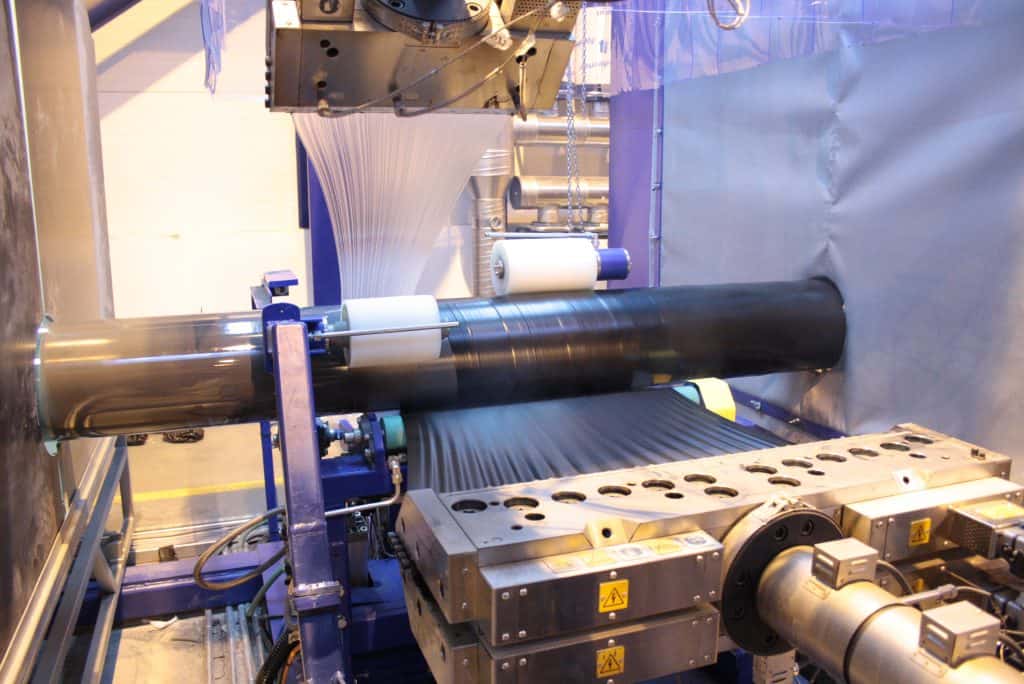

Produces the adhesive sheets that form the layer in a 3LPE/PP coating.

For more information on this topic contact sales@selmers.com

Produces the adhesive sheets that form the layer in a 3LPE/PP coating.

For more information on this topic contact sales@selmers.com

Find below other products that have at least one of the filterable properties of the solution that you are currently viewing. Maybe interesting to you as well?

Biesland 3

1948 RJ BEVERWIJK

The Netherlands

2510 Dickinson Avenue

Dickinson, TX 77539

United States of America

Selmers B.V. – Your Solution Provider – a MeeMaken Company – Copyright © 2022 Selmers B.V. All rights reserved – Privacy Policy

Find what you are looking for, by searching the keyword(s) of your interest