Introduction:

The pre-heating system is crucial in the external blasting process of pipes and other steel objects. The system increases the temperature of the material to prepare it for optimal blasting results.

Solution:

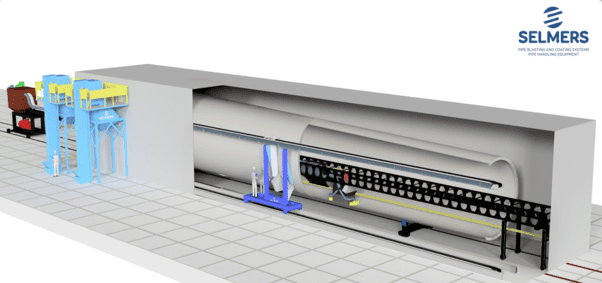

The system must be installed in an external blasting line before the external blaster. The products generally move through the heating cabin by a conveyor. The pre-heater uses gas-fired heaters or induction to increase the product temperature and prepare the product for optimal blasting. By pre-heating the material, the system enhances the effectiveness of the blasting process and improves surface preparation for subsequent coating applications.

Key Features:

- Gas-fired or induction heating options.

- Temperature control system.

- Integrated with conveyor system for continuous operation.

- If necessary, can be combined with heat-resistant rollers or supports.

- Insulated heating chamber.

- Automatic temperature monitoring and adjustment.

- Large product range with easy changeover.

- Efficient heat transfer.

- High heating capacity.

- Integrated control system.

Benefits:

- Precise temperature control: Advanced monitoring and adjustment capabilities ensure accurate and consistent heating across the entire product surface.

- Versatile heating options: Available with gas-fired or induction heating technology to suit different operational requirements and energy sources.

- Possible integration: Designed to work efficiently with existing blasting line equipment and controls for a streamlined production process.

- Robust construction: Built with durable materials to withstand continuous high-temperature operation in demanding industrial environments.

- Automated operation: Minimal need for manual intervention, ensuring consistent performance and minimizing human error.

- Energy efficiency: Utilizes advanced insulation and optional energy recovery systems to minimize heat loss and optimize energy consumption.

- Flexible: Extensive adjustment options for regulating gas and airflow, ensuring the optimal mixture ratio for the heaters.

How it Works:

The pre-heating system uses either gas-fired burners or induction coils to heat the pipes as they move through the heating chamber. The temperature is carefully controlled and monitored to achieve the desired surface temperature without overheating the material. As soon as the pipes exit the pre-heating system, they become ready for treatment by the external blaster.

The Full Scope:

- Heating chamber

- Temperature control system

- Integration with blasting line controls or with integrated control system

- Optional energy recovery system

- Safety systems and emergency shut-offs

Innovate better together!

By mutual learning, we have grown to who we are today. A trustworthy supplier of a multitude of automated solutions. Do you want to optimize performance and reduce risks? Send an email to sales@selmers.com or call +31 (0)251 211 999, or fill in a contact form via https://www.selmers.com/contact and we’ll get back to you.