After a pipe has been coated, pipe end cleaning is necessary to create cutbacks, a clean surface in order to weld the pipe ends to each other to create a pipeline. The first part of a pipe end is assumed to be cleaned, i.e. the part which shall be free from FBE.

Advantages:

High accuracy

Pipe bevel roll to fixate position

Peeling of PE/PP under an angle for better adhesion of field applied joint coating

Easy adjustable for different pipe diameters

How it Works

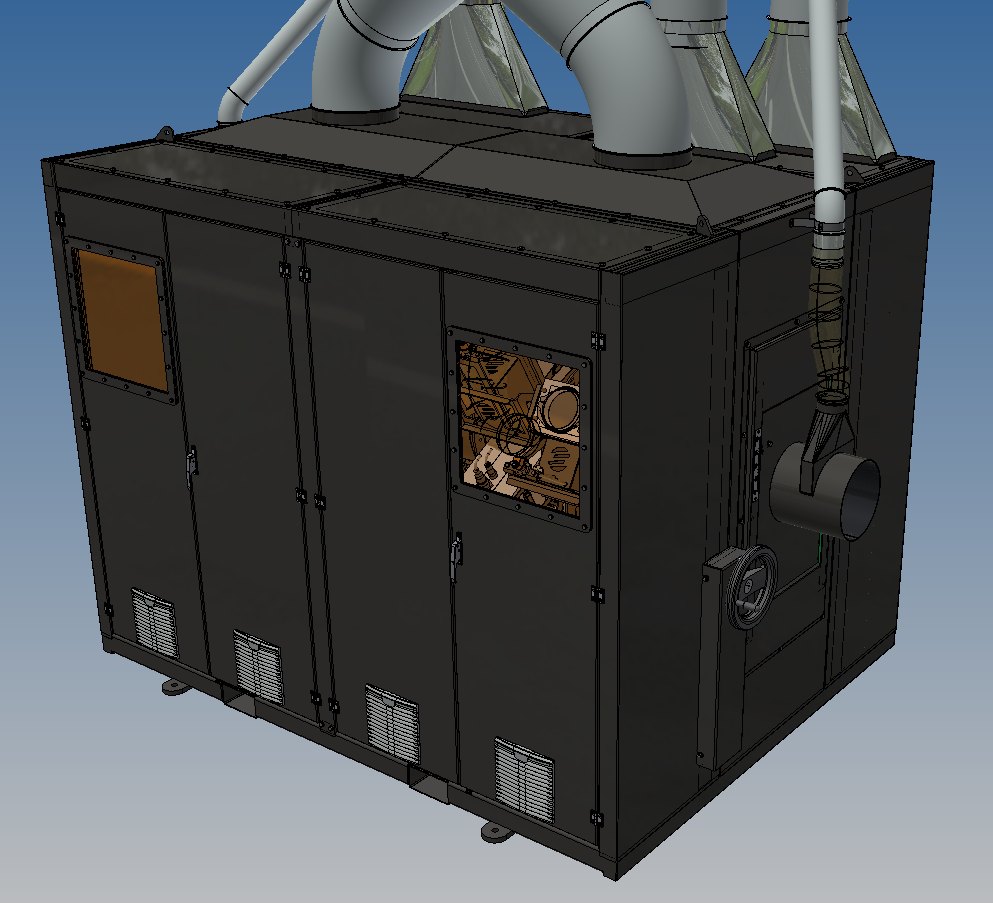

The pipe end knife peeling system is designed to mechanically clean up the pipe ends from PE or PP, leaving the FBE layer in place (epoxy toe). After heating the coating, the system clears the pipe ends over a certain length by means of peeling off the coating under the utilisation of special cutting knives. This provides a smooth transition (chamfer) from the pipe coating to the pipe body by leaving the epoxy toe in place.

The Full Scope:

Pipe support and rotation unit

Pipe end knife peeling units

Electrical coating surface heater

Electrical control system

Electrical control system

Optional:

Shredder system