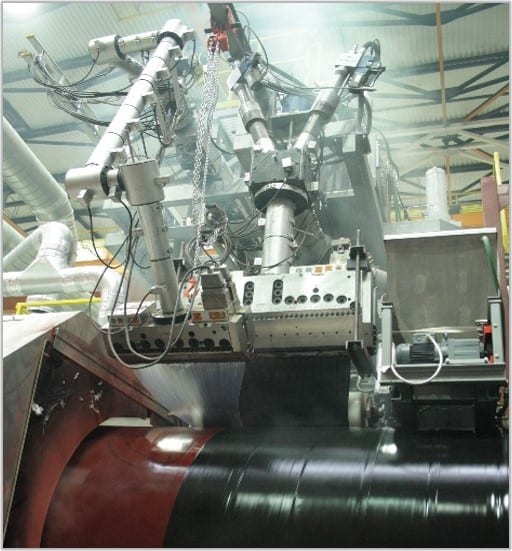

External Blasting & Coating Plant

The Full Scope: External Blasting Equipment: Blasting Conveyor Pre-Heating System (gas-fired / induction) External Blasting System Dust Removal Brush System (Chemical) Treatment Equipment External Pipe Wash System (Alkaline) Chromate Application System Phosphoric Acid Wash System High Pressure Pipe Wash System External Coating Equipment Coating Conveyor Heating System (gas-fired / induction) Tape Application Unit External Coating […]

Phosphoric Acid Wash System

In order to obtain an as clean as possible pipe surface, pipes may be additionally “cleaned” after blasting. In the phosphoric acid wash cleaning process a carefully premixed acid solution is sprayed on the pipe with the goal to remove possible contaminations such as salts (chlorides and sulphates), light oxidation, oil traces, surface dust and/or […]

Internal Blasting System

In the internal mechanical blasting process the pipe surface is blast cleaned with dry-grit using a blast boom system. A highly concentrated stream of steel abrasive particles are projected at the surface. The goal is to remove rust, mill scale and contaminations in order to create the correct cleanness and surface roughness profile, beneficial for coating adhesion. […]

Field Joint (FJ) Blaster

Spread all over the world, a lot of different types of Selmers pipe blasters work successfully; for external and internal pipe coating plants, field joint blasters suitable for S-lay & J-lay vessels, for spoolbases or cross-country usage. Selmers has designed for onshore pipeline construction or spoolbases, a standard program of field joint blasters in 3 […]

Field Joint (FJ) Coater

For more information on this topic contact sales@selmers.com

Weld Seam Compensator

The weld seam compensation system (WSC) can be used to increase the amount of coating material on top of the longitudinal weld seam during application of the PE/PP-layer in a side extrusion pipe coating process. The system operates fully automated and can be integrated in new as well in existing (non-Selmers) extruders. Advantages: Overall top […]

Robotic Process Solutions (General)

Nowadays robotics is an essential component in many modern manufacturing environments. They enable production processes to be faster, flexible, safer and more reliable. Selmers believes that each production facility, big or small, can benefit from the advantages of robotic process solutions. Selmers has developed a range of robotic solutions which are valuable for the pipe […]

Digital Twin Solutions (General)

The next generation of engineering: We have optimized the design processes of our industrial automation into an efficient design street. All this from one database. This improves the qualitative functional designs and knowledge and quality assurance all secured within our PDM. It allows our engineers to focus on our technological innovation preparing you for the […]

Selmers Plant Management System (SPMS)

World’s Digital Demand New economic challenges in the era of global economy are transforming the process industrial environment. Integration of processes, people and organizations is necessary to build on the strengths of each one and optimize performance. Processing plants are facing global competition, environmental regulations, increasing energy costs and tighter product specifications, and still aiming […]

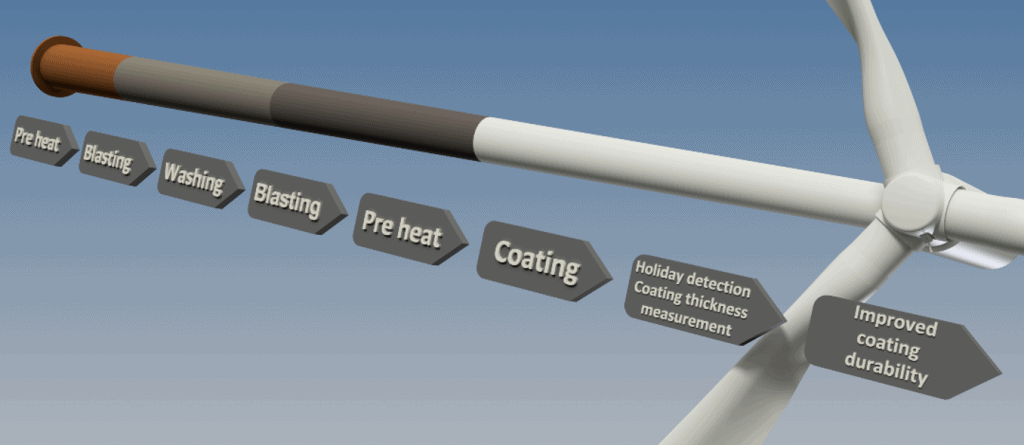

Wind Tower / Monopile Coating Plant

Producers for wind turbines generally use a manual blasting and coating process. Selmers automates this process with a proven system, which increases the capacity, lowers the overall cost and improves the service life of a wind tower or monopile. A Selmers Wind Tower Coating Plant automatically pre-heats, blasts, washes and coats wind towers and monopiles […]